Ball Mill FAQ Guide: Must-Know Tips For Laboratory Or Production.

Adding a ball mill to your lab or small batch production is an important decision that can change the way your samples are ground and processed. Our Ball and Mill FAQ Guide provides insights and answers to help you make an informed decision. Designed for research, teaching, testing, and production, this guide clearly explains common questions about these high energy ball milling.

It covers important topics such as functional principles, application classifications, and choices for ball mill jars and mill balls. The guide also covers key issues such as the composition of the ball mill machine, how to operate it and the maintenance required to keep it running at its optimum. For those laboratories focusing on grinding efficiency, this guide focuses on the selection of the rotational speed of a ball mill and how to determine the ball-to-feed ratio.

As ball mill for grinding become more and more popular around the world, this guide discusses how to purchase an instrument, including warranty, shipping and after-sales service. Whether you are starting from scratch or looking to enhance your sample processing efficiency, this guide will provide you with everything you need for a successful experiment.

What Is a Ball Mill?

Ball mill machine is to use the collision, friction and mixing effect of mill media and material to grind and refine the material to micron or even nano level.

What Are Ball Mills Used For?

A lab ball mill is used to grind, mix and disperse materials.

How Ball Mill Works?

Ball Milling Procedure

When the ball mill operation is started, the ball mill pot is driven by the motor to rotate, and the pot is filled with one-third of the grinding media, which is lifted to a certain height with the rotation of the pot to produce impact and grinding effect with the material.

How To Use a Ball Mill?

Remove the ball mill tank .

Pour the grinding balls into the ball mill , put in one-third of the sample and close the lid.

Place a minimum of two ball mill jars symmetrically into the ball mill, secure and close the lid of the machine.

Turn on the on/off switch and the emergency stop switch.

Run start, adjust the speed,

End of grinding, stop running.

Open the machine cover and check the sample.

What Are The Advantages And Disadvantages Of Ball Mill?

What Is The Application Of Ball Mill?

Ball mill grinding machine is widely used in geology, minerals, metallurgy, electronics, building materials, ceramics, chemical industry, light industry, medicine, environmental protection and other sectors, applicable to electronic ceramics, structural ceramics, high frequency porcelain materials, magnetic materials, lithium cobaltate, lithium manganese acid, catalysts, fluorescent powders, long afterglow luminescent powders, rare-earth polished powders, powdered metals, tungsten, calcium carbide, rubber compounds, electronic glass powders, fuel cells, zinc oxide varistors, Piezoelectric ceramics, nanomaterials, round chip ceramic capacitors, MLCC, thermistors (PTC, NTC), ZnO varistors, dielectric ceramics, alumina ceramics, zirconia ceramics, phosphor, ZnO powder, cobalt oxide powder, Ni-Zn ferrite, Mn-Zn ferrite, and other products in the production field.

What Are The Ball Mill Components?

Parts of ball mill

What Is The Ball Mill Maintenance?

Sweeps up spilled powder or liquid from the machine after use.

The planetary main disk must be cleaned up to avoid damage to the gears and bearings from powder entering the interior.

Regularly check whether the screws of each part are loose.

Clean the air vents regularly.

Regularly check whether the ball mill jar sleeve is loose.

Regularly check the power cord to prevent interruption and damage to the experiment.

Clean the inverter and control switch to keep them dry and clean.

Common problems and solutions of ball mill.

Whether the power, green switch is open. Whether the emergency stop switch is normally open.

The inverter power switch is not displayed after it is opened: First check whether the power supply is normal, and then check whether the power switch is damaged.

Frequency converter has display, press run key motor does not start. : Check whether the plug is tightly inserted first, and then check whether the safety switch is damaged.

What Is The Ball Mill Operating Principle?

The working principle of ball milling machine is based on mechanical impact and friction, through the mill jar rotating to drive the continuous movement of ball mill balls, crushing and grinding of materials.

What Is The Function Of Ball Mill?

The function of high speed ball mill is high efficient preparation and fine grinding.

Laboratory ball mill realizes efficient grinding and mixing of materials through the constant movement, friction and impact of abrasives and grinding balls inside it. Its high grinding efficiency, high crushing fineness and good uniformity of the prepared particles make it an important tool for the preparation of micro and nano materials, powder metallurgy materials, alloy materials, ceramic materials, super-hard materials, electronic encapsulation materials, magnetic materials and so on.

How To Calculate Critical Speed Of Ball Mill?

Critical speed formula (n =42.3/√ D)

The speed is in r / min , D represents the inner diameter of the cylinder (m ).

What Are The Different Types Of Lab Ball Mill?

There are four common types of balls mills

Roll ball Mill Vs Planetary Ball Mill Vs Vibration ball mill

VRM Vs Ball Mill

What Is The Difference Between a Grinding Mill And a Ball Mill?

Wet Ball Milling Vs Dry Ball Milling

What Is The Difference Between a Ball Mill And a Pebble Mill?

How To Calculate Ball Charge In Ball Mill?

The sample and mill balls each occupy one-third of the tank, and one-third is the grinding space.

How Long Does a Ball Mill Take?

Planetary ball mill is a small fine grinding samples of commonly used equipment, grinding time to be determined according to the specific type of sample, the ball material ratio and discharge size, a few minutes to tens of minutes ranging.

The longer the grinding time, the smaller the discharge size.

Different grinding samples and experimental requirements lead to different grinding efficiency.

How Small Will Ball Mill Grind?

As the ball milling's turntable rotates, the center shaft of the ball mill jar moves in a planetary motion and the grinding balls in the jar grind and mix the sample at high speed. Due to the different mixing methods and mixing particles, samples of different materials can be grind to 0. 1 micron.

How To Calculate Ball Mill Capacity?

Cialan company has the capacity of ball mill grinder from 1L to 100L for your choice.

How To Clean Ball Mill Jars?

Commonly cleaned with water, just add scrubbers.

For the ball mill pot has oil, solvent and other water washing can not wash off the material, the milling balls and water plus scrubbing agent can be stuck to the ball mill air rotation. There is no damage to the grinding balls or the tank.

What Is Precautions for Ball Mill Jars Using?

Overloading is prohibited.

Tighten the lid and secure it. Prevent loosening and leakage during grinding.

Run balanced and should be placed symmetrically.

Ventilate, dry and clean.

Solutions For Ball Mill Jar Wear.

Choose the right material of ball mill jar according to the material.

Control the ball milling parameters, do not long time high speed operation.

Reasonable matching of grinding balls, choose the right size and material.

Regularly check the ball mill jar, small wear and tear in time.

What’s Your Minimum Type For Laboratory Use?

The minimum capacity of planetary ball mill is 0.4L, the appearance size of the machine is 530*300*340mm, the weight of the machine is 25kg. we also have the capacity from 1L to 100L for your choice.

Does Your Ball Mill Get To Nano Scale Powder?

Ball milling tool is for soft, hard, brittle and fibrous sample particles of dry grinding, wet grinding and mixing, crushed particle size up to nano-scale.

Can ball mills be cooled?

It can.

Cryogenic ball mill realizes the function similar to refrigeration air conditioner by configuring the ball mill with air cooling, which can provide continuous cold wind air when it is working, and effectively dissipate the heat generated in the grinding process.

How to improve the grinding efficiency of ball mill?

Adjust the appropriate rotational speed.

Optimize the ball material ratio.

Reasonable matching of grinding balls.

Reduce the feed size.

Choose suitable ball milling jars.

Is the higher the speed of the ball mill, the better the grinding efficiency?

No, it doesn't. Higher speed is not equal to better grinding effect.

Too high speed will accelerate the wear and tear of the mechanical parts of the equipment and shorten the service life of the equipment, so it is recommended to adjust the grinding speed according to the actual needs of the material.

What Are The Types Of Mill Jars?

What Are The Different Sizes Of Mill Balls?

How To Choose Ball Size For Ball Mill?

Ball mill grinding samples should be configured to use different sizes of grinding balls in order to grind samples quickly and well.

The ball mill operation gives energy to the grinding balls, and different sizes of grinding balls have different areas to impact and squeeze the sample, which improves the grinding effect.

How Do You Clean Ball Mill Balls?

Gas flushing.

Tissue or dry cloth wiping.

Water washing with cleaning solvent.

Ultrasonic or plasma cleaner cleaning.

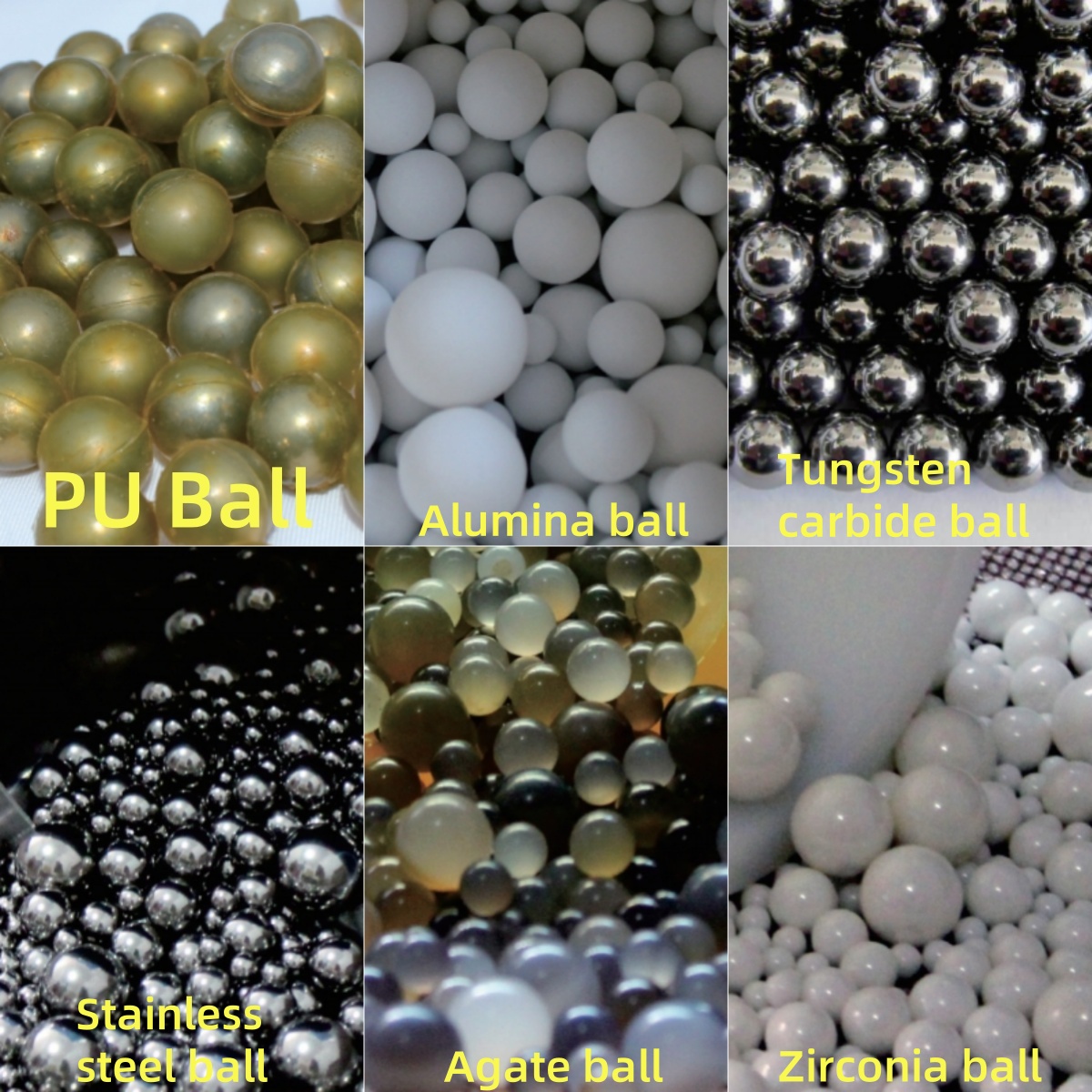

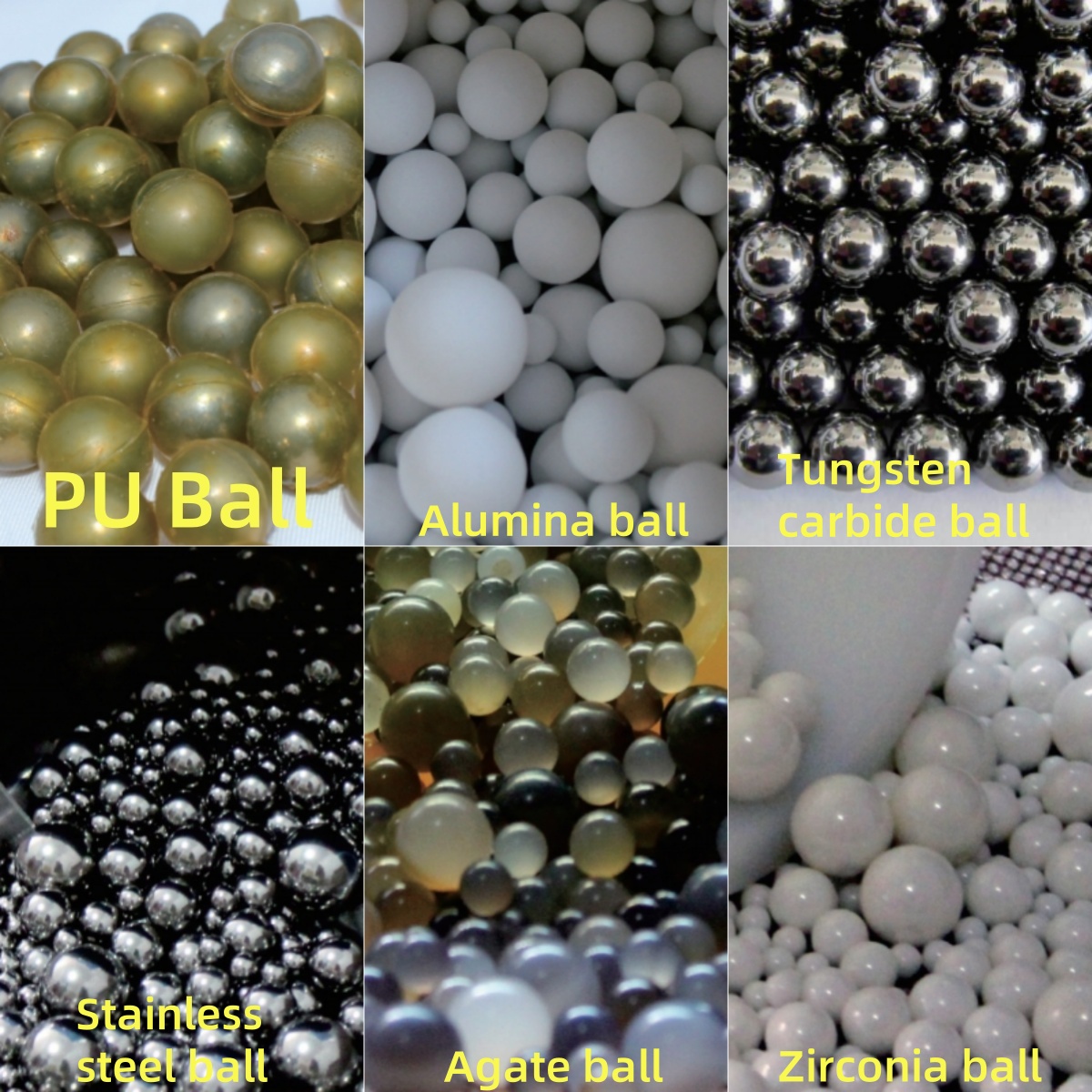

What are the types of ball mill medias?

What Is The Best Media For Ball Mill?

Zirconia balls are currently the most commonly used grinding media in grinding ball mill, on the one hand, the density is large and the grinding efficiency is high. On the other hand it has higher hardness, less abrasion, and is not easy to pollute the pigment.

Generally speaking, the smaller the diameter of zirconia balls, the more contact points between zirconia balls, the larger the effective collision area, and the better the grinding effect.

Why do powders hang up, stick to the wall and false welding in ball mill?

Powder agglomeration and dispersion of particles in the medium of the two directions of the opposite behavior, especially fine and ultrafine particles, in the gas or liquid phase particles due to the interaction force and the formation of polymerization of the state is called agglomeration, the particles are not interrelated with each other, can be free to move in the state is called dispersion.

Agglomeration is a state in which the surface area of primary particles connected by faces is much smaller than the sum of their individual particle compositions, and it is very difficult to re-dispersed in this state.

Attachment refers to the point, the angle of contact with the primary particles or small particles in the attachment of large particles, its total surface area than the cohesion of the body is larger, but smaller than the sum of the composition of individual particles, in the dispersion of easier. Coalescers and agglomerates are also known as secondary particles.

Flocculation is a more loose structure generated due to the increase in the surface area of the system, the increase in surface energy, in order to reduce the surface energy. Generally due to the bridging effect of macromolecular surfactants or water-soluble macromolecules, the particles are strung together into a loose structure like cotton wool clusters, in this structure, the distance between the ions is much larger than the cohesion or agglomeration.

What Is The Best RPM For a Ball Mill?

The selection of the rotational speed of the ball-mill should be adjusted according to the characteristics of the material. Generally speaking, if grinding finer materials, it is recommended to use 0.6 times the critical speed; while for coarser and more brittle materials, 0.7-0.75 times the critical speed can be used to achieve the best grinding effect.

What Is Grinding Aid For Ball Mill?

The sample is deposited on the bottom and inner wall of the ball mill jar, resulting in uneven particle size distribution of the sample and reducing the grinding effect of the sample. The above problems can be solved by grinding aids.

Common grinding aids include ultra-pure water, anhydrous ethanol, hexane, etc.

Precautions for ball mill using

Keep the instrument and electrical parts dry during operation, and do not operate with wet hands.

Pay attention to the continuous working time of the instrument, prohibit overload operation.

Strictly prohibit full load or overload grinding.

When the ball mill is not in use, it must be disconnected from the power supply, in order to prevent accidental contact with the instrument

Keep the inside and outside of the equipment clean and sweep in time.

Non-production needs, do not arbitrarily adjust the parameters of the equipment.

How To Buy A Ball-Milling From China?

Importing Ball-Milling from China can be difficult for those who are new to international imports.

Purchasing from a reputable manufacturer and supplier eliminates hassle of logistics, as they handle the safe and reliable delivery of the product directly to your place.

When buying the ball mill grindings, it is important to keep the following points in mind:

1. Confirm that your selected supplier can securely export and deliver the machine, and ensure that your agreement includes all essential shipping information.

2. Choose the delivery way (by sea, air, or express) based on your preference.

3. Remember to factor in duty imports and taxes when calculating the total cost.

How Does a Manufacturer Deliver The Ball Miller?

Safe shipping is so important as quality manufacturing.

A responsible manufacturer should deliver your conduct meter safely.

Most ball mill machine for laboratory manufacturers use export cartoon case to pack the device.

You should read all the necessary instructions available on the sides of the boxes before boxing.

Is There Any Warranty On Laboratory Ball Mill Machine?

For optimal performance, it is important to regularly maintain your equipment for ball mill container, so it can operate efficiently for an extended period. It is essential to be aware of the warranty coverage for your equipment, as it ensures that any manufacturing issues will be repaired at no additional cost by the supplier. Therefore, it is recommended to purchase a ball mill crusher from a manufacturer that offers warranty services —Cialan.

Reputable ball mill china manufacturers typically provide a 1-year warranty. for example, offers complimentary repair and maintenance services during the first year.

Before purchasing a ball mill equipment, it is advisable to review the warranty period and other associated terms and conditions.

What After-Sale Service Does A Ball Mill Mixer Provide?

The reliable chin a ball mill grinder laboratory suppliers offers the following after-sale services:

1. Secure product delivery.

2. Thorough inspection prior to installation.

3. Complimentary online guidance for device installation and maintenance.

4. Free training for your users.

5. Regular assessments of your ball mill mixing.

Can You Do OEM&ODM For Ball Mill System?

Yes, Cialan can do OEM#OEM for our users, just send us your requirements for ball mill rock crusher.

Where To Find Grinding Mill Manufacturers?

Numerous online directories can connect you with ball mill reactor manufacturers.

A simple search for "top-rated laboratory ball milling instrument manufacturers" yields multiple options. However, it's essential to exercise caution when selecting a manufacturer from online search results. Before making a decision, conduct thorough research on the company's background and reputation. Look up reviews on “Google” and reputable review sites to gauge their credibility.

Additionally, It's also crucial to review their portfolio of request that potential manufacturers share examples of their previous work to ensure they meet your standards.

How To Choose A Right Grinding Ball Mills?

Determine the purpose and needs: Before buying, you need to clarify the purpose and needs of the use of this equipment. What types of materials are to be pulverized or mixed, and what fineness and output are to be achieved. The answers to these questions will help the user choose the right model and size of equipment.

Understand the parameters of the equipment: Maximum loading capacity, grinding media diameter, grinding speed, mixing speed, etc..

What Should You Look For In Good Lab Scale Ball Mill?

The best laboratory ball mill grinder should have high speed, low noise, low vibration, stable and energy-saving operation, and be able to grind materials to micron or nanometer.

It covers important topics such as functional principles, application classifications, and choices for ball mill jars and mill balls. The guide also covers key issues such as the composition of the ball mill machine, how to operate it and the maintenance required to keep it running at its optimum. For those laboratories focusing on grinding efficiency, this guide focuses on the selection of the rotational speed of a ball mill and how to determine the ball-to-feed ratio.

As ball mill for grinding become more and more popular around the world, this guide discusses how to purchase an instrument, including warranty, shipping and after-sales service. Whether you are starting from scratch or looking to enhance your sample processing efficiency, this guide will provide you with everything you need for a successful experiment.

What Is a Ball Mill?

Ball mill machine is to use the collision, friction and mixing effect of mill media and material to grind and refine the material to micron or even nano level.

What Are Ball Mills Used For?

A lab ball mill is used to grind, mix and disperse materials.

How Ball Mill Works?

Ball Milling Procedure

When the ball mill operation is started, the ball mill pot is driven by the motor to rotate, and the pot is filled with one-third of the grinding media, which is lifted to a certain height with the rotation of the pot to produce impact and grinding effect with the material.

How To Use a Ball Mill?

Remove the ball mill tank .

Pour the grinding balls into the ball mill , put in one-third of the sample and close the lid.

Place a minimum of two ball mill jars symmetrically into the ball mill, secure and close the lid of the machine.

Turn on the on/off switch and the emergency stop switch.

Run start, adjust the speed,

End of grinding, stop running.

Open the machine cover and check the sample.

What Are The Advantages And Disadvantages Of Ball Mill?

| Advantages | Disadvantages |

| High grinding efficiency up to micron to nanometer with uniform particle size distribution. Various types of samples can be ground. Various grinding methods and conditions. Large grinding capacity. Good sealing. A wide range of volume and material grinding jars are available. |

Costs are higher than conventional ball mills. High rotational speeds and impacts can generate significant noise. Mill media tends to wear out after long-term use and can contaminate samples. It is large in size and inconvenient for transportation. When running at high speed, the friction between material and medium generates a lot of heat, which needs to be equipped with cooling system. |

What Is The Application Of Ball Mill?

Ball mill grinding machine is widely used in geology, minerals, metallurgy, electronics, building materials, ceramics, chemical industry, light industry, medicine, environmental protection and other sectors, applicable to electronic ceramics, structural ceramics, high frequency porcelain materials, magnetic materials, lithium cobaltate, lithium manganese acid, catalysts, fluorescent powders, long afterglow luminescent powders, rare-earth polished powders, powdered metals, tungsten, calcium carbide, rubber compounds, electronic glass powders, fuel cells, zinc oxide varistors, Piezoelectric ceramics, nanomaterials, round chip ceramic capacitors, MLCC, thermistors (PTC, NTC), ZnO varistors, dielectric ceramics, alumina ceramics, zirconia ceramics, phosphor, ZnO powder, cobalt oxide powder, Ni-Zn ferrite, Mn-Zn ferrite, and other products in the production field.

What Are The Ball Mill Components?

Parts of ball mill

| Sun Wheel | A large gear disk fixed in the center, connected to a motor through a spindle, drives a number of grinding jars in planetary motion. |

| Planetary Carrier | A rotating carrier for mounting the grinding canisters, which rotates around the planetary disk while the canisters themselves rotate at high speed. |

| Transmission Gear Set | Rotating gears, self-rotating gears. |

| Grinding Jars | Grinding jars made of different materials to hold the material and grinding media. |

| Grinding Media | Grinding balls made of various materials. |

| Drive and control system | Motor, control panel. |

| Cooling and Temperature Control System | low temperature grinding, to prevent high temperature. |

What Is The Ball Mill Maintenance?

Sweeps up spilled powder or liquid from the machine after use.

The planetary main disk must be cleaned up to avoid damage to the gears and bearings from powder entering the interior.

Regularly check whether the screws of each part are loose.

Clean the air vents regularly.

Regularly check whether the ball mill jar sleeve is loose.

Regularly check the power cord to prevent interruption and damage to the experiment.

Clean the inverter and control switch to keep them dry and clean.

Common problems and solutions of ball mill.

Whether the power, green switch is open. Whether the emergency stop switch is normally open.

The inverter power switch is not displayed after it is opened: First check whether the power supply is normal, and then check whether the power switch is damaged.

Frequency converter has display, press run key motor does not start. : Check whether the plug is tightly inserted first, and then check whether the safety switch is damaged.

What Is The Ball Mill Operating Principle?

The working principle of ball milling machine is based on mechanical impact and friction, through the mill jar rotating to drive the continuous movement of ball mill balls, crushing and grinding of materials.

What Is The Function Of Ball Mill?

The function of high speed ball mill is high efficient preparation and fine grinding.

Laboratory ball mill realizes efficient grinding and mixing of materials through the constant movement, friction and impact of abrasives and grinding balls inside it. Its high grinding efficiency, high crushing fineness and good uniformity of the prepared particles make it an important tool for the preparation of micro and nano materials, powder metallurgy materials, alloy materials, ceramic materials, super-hard materials, electronic encapsulation materials, magnetic materials and so on.

How To Calculate Critical Speed Of Ball Mill?

Critical speed formula (n =42.3/√ D)

The speed is in r / min , D represents the inner diameter of the cylinder (m ).

What Are The Different Types Of Lab Ball Mill?

There are four common types of balls mills

| Planetary Ball Mill | Planetary ball mill is a powder processing equipment for laboratory or small batch production. When the turntable rotates, the center axis of the ball milling jar makes planetary motion, and the grinding balls in the jar grind and mix the samples in high-speed motion. |

| Stirred Ball Mill | The Stirred Ball Mill is a device for pulverizing, mixing or dispersing materials by means of grinding media driven by a high-speed rotating agitator. |

| Vibration Ball Mil | Vibrating ball mill utilizes electric motor to drive the vibration generator to produce continuous vibration, so that the cylinder body does small amplitude, high frequency continuous movement. Due to the self-rotation and relative motion of the grinding medium in the cylinder, the material in the cylinder is continuously crushed, stripped and ground into uniform powder. |

| Roll ball mill | The roller ball mill utilizes the principle of rolling and friction to make the grinding ball rotate in the grinding drum, and produce friction with the surface of the workpiece to be ground to achieve the grinding effect. |

Roll ball Mill Vs Planetary Ball Mill Vs Vibration ball mill

| Roll ball Mill | Planetary Ball Mill | Vibration ball mill |

| The running part of the roll ball mill is a rotatable cylindrical drum. When the equipment is running, the drum will bring the grinding balls inside to the top of the drum, and then the grinding balls will fall down freely because of their own gravity and smash the materials. | The planetary ball mill has a high-speed rotating circular disk, on which there are four uniformly mounted tanks, in which sealed ball milling jars can be placed, and grinding balls and materials are put into the ball milling jars. When the equipment is in operation, the main wheel rotates at high speed, and the canisters drive the ball milling canisters to rotate in the opposite direction, and the grinding balls inside the canisters are endowed with huge grinding energy under the superposition of the two rotating in opposite directions, and the samples are impacted, squeezed and rubbed. | Vibrating ball mill is driven by the vibrating mechanical structure to carry out the movement of the ball mill jar, which is divided into two-dimensional vibrating ball mill and three-dimensional vibrating ball mill. When the equipment is in operation, the ball mill jar fixed on the mechanical structure is brought to action by high frequency vibration, the grinding balls in the jar impact, extrusion and friction on the sample, which produces more grinding energy than the planetary ball mill. |

VRM Vs Ball Mill

| Vertical Roller Mill | Ball Mill |

| Vertically mounted grinding disk with multiple rollers, the material is crushed and pulverized on the grinding disk by the pressure and shear force of the rollers. | Horizontally rotating cylinder filled with grinding media, when the cylinder rotates, the grinding balls grind the material through the impact and rolling friction generated by the free fall. |

What Is The Difference Between a Grinding Mill And a Ball Mill?

| Grinding Mill | Ball Mill |

| Broadly refers to all the equipment used to crush and grind materials, such as high-speed rotating blades, hammers, grinding discs or grinding rolls, etc. directly on the material to apply shear force, impact or extrusion force, grinding materials. | Belongs to a subdivided type of grinding machine, the core feature is to use the grinding media in the cylinder to crush the material by impact and friction. |

Wet Ball Milling Vs Dry Ball Milling

| Wet Ball Milling | Dry Ball Milling |

| It refers to the material moisture content of more than 50%, the raw material is suspended in the carrier liquid stream for grinding, and appropriate addition of dispersants and other additives to help the grinding process. Smaller level particles can be obtained, but the production cycle is long, the post-treatment is complicated and the cost is high. | It means that the moisture content of the material does not exceed 4% when the grinding operation is carried out. The production cycle is short, the post-treatment is simple and the cost is low. However, the powder in the grinding process is easy to agglomerate, and it is difficult to obtain smaller grade powder. The temperature of powder in the grinding process is easy to rise. |

What Is The Difference Between a Ball Mill And a Pebble Mill?

| Ball Mill | Pebble Mill |

| Grinding media are mainly zirconia, agate, etc. High hardness materials. |

Grinding media is mainly pebble. Medium to low hardness materials. |

How To Calculate Ball Charge In Ball Mill?

The sample and mill balls each occupy one-third of the tank, and one-third is the grinding space.

How Long Does a Ball Mill Take?

Planetary ball mill is a small fine grinding samples of commonly used equipment, grinding time to be determined according to the specific type of sample, the ball material ratio and discharge size, a few minutes to tens of minutes ranging.

The longer the grinding time, the smaller the discharge size.

Different grinding samples and experimental requirements lead to different grinding efficiency.

How Small Will Ball Mill Grind?

As the ball milling's turntable rotates, the center shaft of the ball mill jar moves in a planetary motion and the grinding balls in the jar grind and mix the sample at high speed. Due to the different mixing methods and mixing particles, samples of different materials can be grind to 0. 1 micron.

How To Calculate Ball Mill Capacity?

Cialan company has the capacity of ball mill grinder from 1L to 100L for your choice.

How To Clean Ball Mill Jars?

Commonly cleaned with water, just add scrubbers.

For the ball mill pot has oil, solvent and other water washing can not wash off the material, the milling balls and water plus scrubbing agent can be stuck to the ball mill air rotation. There is no damage to the grinding balls or the tank.

What Is Precautions for Ball Mill Jars Using?

Overloading is prohibited.

Tighten the lid and secure it. Prevent loosening and leakage during grinding.

Run balanced and should be placed symmetrically.

Ventilate, dry and clean.

Solutions For Ball Mill Jar Wear.

Choose the right material of ball mill jar according to the material.

Control the ball milling parameters, do not long time high speed operation.

Reasonable matching of grinding balls, choose the right size and material.

Regularly check the ball mill jar, small wear and tear in time.

What’s Your Minimum Type For Laboratory Use?

The minimum capacity of planetary ball mill is 0.4L, the appearance size of the machine is 530*300*340mm, the weight of the machine is 25kg. we also have the capacity from 1L to 100L for your choice.

Does Your Ball Mill Get To Nano Scale Powder?

Ball milling tool is for soft, hard, brittle and fibrous sample particles of dry grinding, wet grinding and mixing, crushed particle size up to nano-scale.

Can ball mills be cooled?

It can.

Cryogenic ball mill realizes the function similar to refrigeration air conditioner by configuring the ball mill with air cooling, which can provide continuous cold wind air when it is working, and effectively dissipate the heat generated in the grinding process.

How to improve the grinding efficiency of ball mill?

Adjust the appropriate rotational speed.

Optimize the ball material ratio.

Reasonable matching of grinding balls.

Reduce the feed size.

Choose suitable ball milling jars.

Is the higher the speed of the ball mill, the better the grinding efficiency?

No, it doesn't. Higher speed is not equal to better grinding effect.

Too high speed will accelerate the wear and tear of the mechanical parts of the equipment and shorten the service life of the equipment, so it is recommended to adjust the grinding speed according to the actual needs of the material.

What Are The Types Of Mill Jars?

What Are The Different Sizes Of Mill Balls?

| Mill Balls | Diameter | Customized |

| Iron Core PU Balls | Φ15mm-Φ30mm | Yes |

| Zirconia Mill Ball | Φ1mm-Φ30mm | Yes |

| Alumina Mill Ball | Φ1mm-Φ50mm | Yes |

| Agate Mill Ball | 3,5,8,10,12,15,20mm | Yes |

| Stainless Steel Mill Ball | Φ1mm-Φ30mm | Yes |

| Tungsten Carbide Mill Ball | Φ15mm-Φ30mm | Yes |

How To Choose Ball Size For Ball Mill?

Ball mill grinding samples should be configured to use different sizes of grinding balls in order to grind samples quickly and well.

The ball mill operation gives energy to the grinding balls, and different sizes of grinding balls have different areas to impact and squeeze the sample, which improves the grinding effect.

How Do You Clean Ball Mill Balls?

Gas flushing.

Tissue or dry cloth wiping.

Water washing with cleaning solvent.

Ultrasonic or plasma cleaner cleaning.

What are the types of ball mill medias?

What Is The Best Media For Ball Mill?

Zirconia balls are currently the most commonly used grinding media in grinding ball mill, on the one hand, the density is large and the grinding efficiency is high. On the other hand it has higher hardness, less abrasion, and is not easy to pollute the pigment.

Generally speaking, the smaller the diameter of zirconia balls, the more contact points between zirconia balls, the larger the effective collision area, and the better the grinding effect.

Why do powders hang up, stick to the wall and false welding in ball mill?

Powder agglomeration and dispersion of particles in the medium of the two directions of the opposite behavior, especially fine and ultrafine particles, in the gas or liquid phase particles due to the interaction force and the formation of polymerization of the state is called agglomeration, the particles are not interrelated with each other, can be free to move in the state is called dispersion.

Agglomeration is a state in which the surface area of primary particles connected by faces is much smaller than the sum of their individual particle compositions, and it is very difficult to re-dispersed in this state.

Attachment refers to the point, the angle of contact with the primary particles or small particles in the attachment of large particles, its total surface area than the cohesion of the body is larger, but smaller than the sum of the composition of individual particles, in the dispersion of easier. Coalescers and agglomerates are also known as secondary particles.

Flocculation is a more loose structure generated due to the increase in the surface area of the system, the increase in surface energy, in order to reduce the surface energy. Generally due to the bridging effect of macromolecular surfactants or water-soluble macromolecules, the particles are strung together into a loose structure like cotton wool clusters, in this structure, the distance between the ions is much larger than the cohesion or agglomeration.

What Is The Best RPM For a Ball Mill?

The selection of the rotational speed of the ball-mill should be adjusted according to the characteristics of the material. Generally speaking, if grinding finer materials, it is recommended to use 0.6 times the critical speed; while for coarser and more brittle materials, 0.7-0.75 times the critical speed can be used to achieve the best grinding effect.

What Is Grinding Aid For Ball Mill?

The sample is deposited on the bottom and inner wall of the ball mill jar, resulting in uneven particle size distribution of the sample and reducing the grinding effect of the sample. The above problems can be solved by grinding aids.

Common grinding aids include ultra-pure water, anhydrous ethanol, hexane, etc.

Precautions for ball mill using

Keep the instrument and electrical parts dry during operation, and do not operate with wet hands.

Pay attention to the continuous working time of the instrument, prohibit overload operation.

Strictly prohibit full load or overload grinding.

When the ball mill is not in use, it must be disconnected from the power supply, in order to prevent accidental contact with the instrument

Keep the inside and outside of the equipment clean and sweep in time.

Non-production needs, do not arbitrarily adjust the parameters of the equipment.

How To Buy A Ball-Milling From China?

Importing Ball-Milling from China can be difficult for those who are new to international imports.

Purchasing from a reputable manufacturer and supplier eliminates hassle of logistics, as they handle the safe and reliable delivery of the product directly to your place.

When buying the ball mill grindings, it is important to keep the following points in mind:

1. Confirm that your selected supplier can securely export and deliver the machine, and ensure that your agreement includes all essential shipping information.

2. Choose the delivery way (by sea, air, or express) based on your preference.

3. Remember to factor in duty imports and taxes when calculating the total cost.

How Does a Manufacturer Deliver The Ball Miller?

Safe shipping is so important as quality manufacturing.

A responsible manufacturer should deliver your conduct meter safely.

Most ball mill machine for laboratory manufacturers use export cartoon case to pack the device.

You should read all the necessary instructions available on the sides of the boxes before boxing.

Is There Any Warranty On Laboratory Ball Mill Machine?

For optimal performance, it is important to regularly maintain your equipment for ball mill container, so it can operate efficiently for an extended period. It is essential to be aware of the warranty coverage for your equipment, as it ensures that any manufacturing issues will be repaired at no additional cost by the supplier. Therefore, it is recommended to purchase a ball mill crusher from a manufacturer that offers warranty services —Cialan.

Reputable ball mill china manufacturers typically provide a 1-year warranty. for example, offers complimentary repair and maintenance services during the first year.

Before purchasing a ball mill equipment, it is advisable to review the warranty period and other associated terms and conditions.

What After-Sale Service Does A Ball Mill Mixer Provide?

The reliable chin a ball mill grinder laboratory suppliers offers the following after-sale services:

1. Secure product delivery.

2. Thorough inspection prior to installation.

3. Complimentary online guidance for device installation and maintenance.

4. Free training for your users.

5. Regular assessments of your ball mill mixing.

Can You Do OEM&ODM For Ball Mill System?

Yes, Cialan can do OEM#OEM for our users, just send us your requirements for ball mill rock crusher.

Where To Find Grinding Mill Manufacturers?

Numerous online directories can connect you with ball mill reactor manufacturers.

A simple search for "top-rated laboratory ball milling instrument manufacturers" yields multiple options. However, it's essential to exercise caution when selecting a manufacturer from online search results. Before making a decision, conduct thorough research on the company's background and reputation. Look up reviews on “Google” and reputable review sites to gauge their credibility.

Additionally, It's also crucial to review their portfolio of request that potential manufacturers share examples of their previous work to ensure they meet your standards.

How To Choose A Right Grinding Ball Mills?

Determine the purpose and needs: Before buying, you need to clarify the purpose and needs of the use of this equipment. What types of materials are to be pulverized or mixed, and what fineness and output are to be achieved. The answers to these questions will help the user choose the right model and size of equipment.

Understand the parameters of the equipment: Maximum loading capacity, grinding media diameter, grinding speed, mixing speed, etc..

What Should You Look For In Good Lab Scale Ball Mill?

The best laboratory ball mill grinder should have high speed, low noise, low vibration, stable and energy-saving operation, and be able to grind materials to micron or nanometer.