How to use an electric centrifugal divider and what its function?

Electric centrifugal divider and its applications.

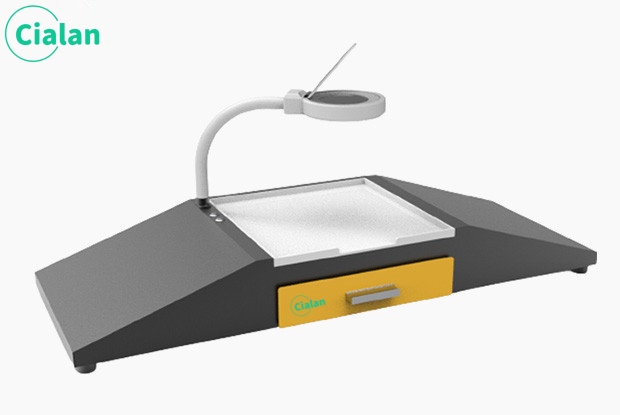

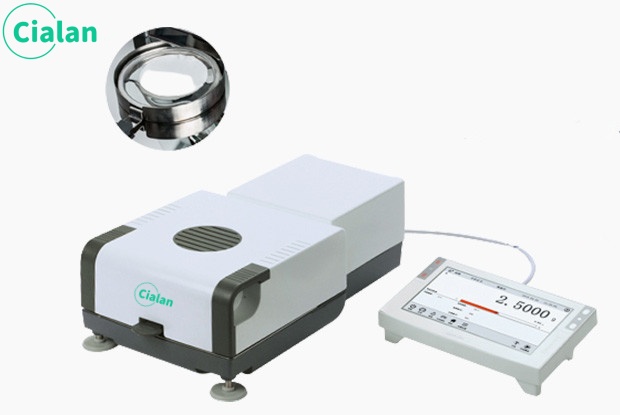

1.The electric centrifugal sample divider is also called an electric sample divider. The centrifugal sample divider is based on the principle of different centrifugal forces generated by things of different weights in the centrifuge to distinguish bad seeds and impurities in seeds.

2.This centrifugal sampler is suitable for precise sampling of various seeds, grains, and feeds. It can achieve precise sampling of large batches of samples within seconds, especially for small grain crops. The rotating speed is adjustable, and the appropriate rotating speed can be adjusted according to different seeds, and the sampling speed is fast. The motor drives the rotating aluminum plate under the feeding funnel to perform centrifugal motion to complete the rapid and uniform sampling and mixing process.

3.The electric centrifugal sample divider adopts a bell-type structure and uses copper as the material of the sample divider. Therefore, it has high recovery elasticity and corrosion resistance, and can also ensure the accuracy and stability of sample divider accuracy. It has a simple structure. , easy to use, uniform sample mixing, and small sampling error. Therefore, the bell tripod type sampler does have a good application in crop seed sampling work, especially in grain crop sampling work.

4.When sampling grain crops, this product can accurately separate our grains according to particle size, which greatly improves our work efficiency and reduces our labor and labor costs. At the same time, due to its accuracy, it provides us with Grain cultivation provides excellent seeds, which improves the yield and quality of crops.

Main features.

1. The rotation speed is adjustable, and the appropriate rotation speed can be adjusted according to different seeds.

2. Exquisite and beautiful appearance, chrome-plated surface, anti-rust and anti-corrosion.

3. Accurate sample dividing, with a one-time sample dividing accuracy of ±0.5%, which makes up for the shortcomings of traditional gravity-type sample dividers that require multiple sample dividers.

4. The interior is smooth to ensure no residue of samples inside.

5. The sample dividing speed is fast. The motor drives the rotating aluminum plate under the feeding funnel to perform centrifugal motion to complete the rapid and uniform sample dividing and mixing process.

6. It is especially suitable for small and medium grain grains, making up for the inconvenience of using different specifications of instruments for different seeds in traditional sample dividers.

How to use the seed divider?

1. Clean the inside of the sample divider and close the drain and half switch.

2. Place the receiver and pour the sample evenly into the funnel from a position 5 cm above the mouth of the sample divider.

3. After scraping the sample, open the funnel switch, and the sample will flow into the two receivers respectively. The sample will be poured into the funnel at the same time. Continue to mix twice, then take out one receiver, and continue to divide the sample according to the above operation method until one receiver until the sample in the container approaches the weight of the required specimen.

4. Adjust the speed: According to different materials, first adjust the motor to the appropriate speed (it can also be adjusted according to work needs during work)

5. Check whether the instrument is turned off. After confirmation, turn on the power and load the grain into the funnel (note: 1. The grain must exceed 1/2 of the funnel; 2. When loading into the funnel, the seeds must always be poured out. in the center), turn on the power, and the instrument begins to sample rapidly. Completed within 5 seconds.

6. If you need to achieve better accuracy, you can repeat it twice.

Precautions.

1. During the sample dividing process, the speed of pouring the sample should be uniform. Only in this way can the inconsistent number of samples obtained be avoided;

2. Before pouring the sample into the sample container, the sample should be in a horizontal state rather than funnel-shaped. If it is funnel-shaped, it should be flattened before proceeding to the next step.

3. This centrifugal sample divider should be placed in a horizontal state, otherwise it may result in the quantity of the two divided samples being different;

4. Seeds that have fallen outside the sample container cannot be picked up to any side that has been separated. Seeds with lemma shells should be sampled several times to fully mix the samples. When the number of samples cannot meet the When the low quantity required for the test is required, the sample should be divided again instead of randomly taking a certain number of samples from the other half and putting them into it.

Summary.

The electric centrifugal sample divider can distinguish bad seeds and impurities in seeds based on the principle of different centrifugal forces generated by things of different weights in the centrifuge. This centrifugal sampler is suitable for precise sampling of various seeds, grains, and feeds, and it also brings convenience to workers in related industries.

1.The electric centrifugal sample divider is also called an electric sample divider. The centrifugal sample divider is based on the principle of different centrifugal forces generated by things of different weights in the centrifuge to distinguish bad seeds and impurities in seeds.

2.This centrifugal sampler is suitable for precise sampling of various seeds, grains, and feeds. It can achieve precise sampling of large batches of samples within seconds, especially for small grain crops. The rotating speed is adjustable, and the appropriate rotating speed can be adjusted according to different seeds, and the sampling speed is fast. The motor drives the rotating aluminum plate under the feeding funnel to perform centrifugal motion to complete the rapid and uniform sampling and mixing process.

3.The electric centrifugal sample divider adopts a bell-type structure and uses copper as the material of the sample divider. Therefore, it has high recovery elasticity and corrosion resistance, and can also ensure the accuracy and stability of sample divider accuracy. It has a simple structure. , easy to use, uniform sample mixing, and small sampling error. Therefore, the bell tripod type sampler does have a good application in crop seed sampling work, especially in grain crop sampling work.

4.When sampling grain crops, this product can accurately separate our grains according to particle size, which greatly improves our work efficiency and reduces our labor and labor costs. At the same time, due to its accuracy, it provides us with Grain cultivation provides excellent seeds, which improves the yield and quality of crops.

Main features.

1. The rotation speed is adjustable, and the appropriate rotation speed can be adjusted according to different seeds.

2. Exquisite and beautiful appearance, chrome-plated surface, anti-rust and anti-corrosion.

3. Accurate sample dividing, with a one-time sample dividing accuracy of ±0.5%, which makes up for the shortcomings of traditional gravity-type sample dividers that require multiple sample dividers.

4. The interior is smooth to ensure no residue of samples inside.

5. The sample dividing speed is fast. The motor drives the rotating aluminum plate under the feeding funnel to perform centrifugal motion to complete the rapid and uniform sample dividing and mixing process.

6. It is especially suitable for small and medium grain grains, making up for the inconvenience of using different specifications of instruments for different seeds in traditional sample dividers.

How to use the seed divider?

1. Clean the inside of the sample divider and close the drain and half switch.

2. Place the receiver and pour the sample evenly into the funnel from a position 5 cm above the mouth of the sample divider.

3. After scraping the sample, open the funnel switch, and the sample will flow into the two receivers respectively. The sample will be poured into the funnel at the same time. Continue to mix twice, then take out one receiver, and continue to divide the sample according to the above operation method until one receiver until the sample in the container approaches the weight of the required specimen.

4. Adjust the speed: According to different materials, first adjust the motor to the appropriate speed (it can also be adjusted according to work needs during work)

5. Check whether the instrument is turned off. After confirmation, turn on the power and load the grain into the funnel (note: 1. The grain must exceed 1/2 of the funnel; 2. When loading into the funnel, the seeds must always be poured out. in the center), turn on the power, and the instrument begins to sample rapidly. Completed within 5 seconds.

6. If you need to achieve better accuracy, you can repeat it twice.

Precautions.

1. During the sample dividing process, the speed of pouring the sample should be uniform. Only in this way can the inconsistent number of samples obtained be avoided;

2. Before pouring the sample into the sample container, the sample should be in a horizontal state rather than funnel-shaped. If it is funnel-shaped, it should be flattened before proceeding to the next step.

3. This centrifugal sample divider should be placed in a horizontal state, otherwise it may result in the quantity of the two divided samples being different;

4. Seeds that have fallen outside the sample container cannot be picked up to any side that has been separated. Seeds with lemma shells should be sampled several times to fully mix the samples. When the number of samples cannot meet the When the low quantity required for the test is required, the sample should be divided again instead of randomly taking a certain number of samples from the other half and putting them into it.

Summary.

The electric centrifugal sample divider can distinguish bad seeds and impurities in seeds based on the principle of different centrifugal forces generated by things of different weights in the centrifuge. This centrifugal sampler is suitable for precise sampling of various seeds, grains, and feeds, and it also brings convenience to workers in related industries.