What is basic principle and application areas of FTIR spectroscopy?

An introduction what is the concept of FTIR spectroscopy

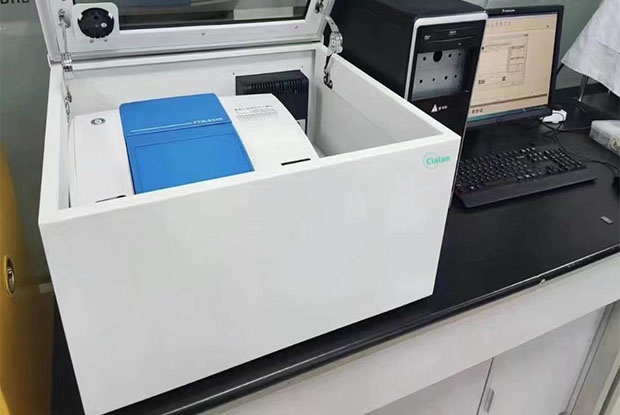

Fourier Transform Infrared Spectrometer (Abbreviated as FTIR Spectrometer), referred to as Fourier Infrared Spectrometer. It is different from the principle of dispersive infrared spectroscopy. It is an infrared spectrometer developed based on the principle of Fourier transformation of the interfered infrared light. It mainly consists of the infrared light source, aperture, and interferometer (beam splitter, moving mirror, fixed mirror), sample chamber, detector, and various infrared reflectors, lasers, control circuit boards, and power supplies.

It can conduct qualitative and quantitative analysis of samples and is widely used in fields such as pharmaceutical and chemical industry, geology and mining, petroleum, coal, environmental protection, customs, gem identification, criminal investigation and identification, etc.

Working principle of FITR.

The light emitted by the light source is divided into two beams by a beam splitter (similar to a half mirror). One beam reaches the moving mirror through transmission, and the other beam reaches the fixed mirror after reflection. The two beams of light are reflected by the fixed mirror and the moving mirror respectively and then return to the beam splitter. The moving mirror moves linearly at a constant speed.

Therefore, the two beams of light split by the beam splitter form an optical path difference and cause interference. After the interference light meets the beam splitter, it passes through the sample cell. After passing through the sample, the interference light containing sample information reaches the detector, and then the signal is processed through the Fourier transform, and finally the infrared absorption of transmittance or absorbance with wave number or wavelength is obtained.

The main features of FTIR.

1. High signal-to-noise ratio: FTIR analysis use fewer optical components and no gratings or prism beam splitters, which reduces light loss and further increases the light signal through interference, so the radiation intensity reaching the detector is large. , high signal-to-noise ratio.

2. Good reproducibility: FTIR spectrophotometer uses Fourier transform to process the light signal, which avoids errors caused by motor-driven grating spectroscopy, so the reproducibility is relatively good.

3. Fast scanning speed: FTIR machine collects data according to the whole band, and the spectrum obtained is the result of averaging multiple data collections, it only takes one to several seconds to complete a complete data collection, while dispersion Type instruments need to test only a narrow frequency range at any moment, and a complete data collection takes ten to twenty minutes.

Simply put, infrared spectroscopy has strong characteristics, fast analysis, does not destroy the sample, requires less sample, is easy to operate, can analyze samples in various states, has high analytical sensitivity, and has a wide range of applications (solid, liquid or It can be applied to gaseous samples; inorganic, organic, and polymer compounds can be detected) and other characteristics. It is combined with chromatography (GC-IR) or TGA (TGA-IR) to have powerful qualitative functions.

What problems can FTIR solve?

① Identification of known objects;

② Structural identification of unknown substances;

③ Quantitative analysis of special materials;

④Micro-infrared can analyze trace substances such as residues on the product surface, powder/liquid precipitated on the surface, suspected oxidation, corrosion, foreign matter, the introduction of foreign ingredients, etc. on the product surface.

Application of FTIR in the field of material testing.

1. Identification of known objects

Compare the infrared spectrum of the sample with the standard infrared spectrum. The similarity and purity of the two compounds are determined based on the consistency of spectral peak positions, wave numbers, peak shapes, and other characteristics.

The infrared spectrum of the sample and the standard infrared spectrum have a high consistency in the three characteristics of peak position, wave number, and peak shape. It can be judged that the main components of the two are the same and have close purity. At the same time, the software gives The matching value of the two spectra reached 94.06%, and the spectral overlap was high.

2. Determining the consistency of polymer materials

Due to the different types of material groups and the different ways of group arrangement, this difference will be reflected in different peaks in the infrared spectrum. Therefore, there will be certain differences in the infrared spectral fingerprints. By comparing the infrared spectra, the differences in the compounds contained in the samples or the differences in the compound structures can be obtained, thereby determining the material consistency issues of different samples. Usually, material consistency also needs to be combined with a multi-dimensional comprehensive analysis of product component content, product physical and chemical properties, etc. to obtain better consistency analysis results.

Application areas: unprocessed plastic raw materials (pellets) or processed homogeneous plastic parts (such as casings, supporting live parts, etc.); printed circuit boards (PCB boards).

Purpose of material consistency determination.

①. Solve product anomalies in terms of materials;

②. Monitor products to determine whether the materials are of the same composition, batch, and manufacturer;

③. Effectively control plastic material suppliers from using excessive amounts of recycled materials or leftover materials;

④. Reversely analyze products, accurately characterize unknown materials, and save costs.

3. Foreign materials analysis.

Microinfrared spectroscopy is the most commonly used analytical method in the analysis of organic foreign matter. The chemical composition of the foreign matter can be determined based on the absorption peaks of the functional groups in the infrared spectrum of the foreign matter. The simple method is to search the spectral library through the instrument software and compare it with the standard infrared spectrum in the library to determine the chemical composition of the foreign matter. In the face of The more complicated situation is to use FTIR instrument with other detection equipment to obtain the composition of foreign matter or information related to foreign matter.

Application fields: For surface pollutants, precipitates, and other abnormal substances on products, such as particles, oily substances, mist, spots, etc. on the product surface, FTIR testing mainly analyzes organic foreign matter.

The purpose of foreign matter analysis: to conduct composition analysis of foreign matter, impurities, or unknown matter that appear during industrial production, storage, and use, to find and track the causes and sources of foreign matter, thereby effectively preventing the generation of foreign matter and reducing economic losses of enterprises.

Usually, the tests using ATR-FTIR to analyze foreign matter are as follows.

① Collect foreign objects on the infrared window

② Collect the infrared spectrum of foreign matter

③ Analyze the infrared spectrum of the foreign matter, obtain the results, and infer the source of the foreign matter

4. Cure rate test

The curing rate is a characterization of the degree of curing of a colloidal sample before and after physical curing or chemical curing.

Using FTIR spectroscopy equipment to test the curing rate includes: observing the breakage and reorganization of the functional groups of the sample during the curing process; the mechanism of the curing reaction; judging the degree of the curing reaction; testing the curing rate of the sample, etc.

Application fields: Suitable for thermosetting resins such as epoxy resin, polyurethane resin, vinyl addition polymerization silicone rubber, etc.

Purpose of the curing rate test: The curing rate (cross-linking degree) test can effectively observe the reaction degree of the cross-linked cured sample and control the material properties.

Click here to get comprehensive FAQ Guide about FTIR spectrophy equipment.