Knowledge about magnetic stirrer

What is a magnetic stirrer?

A magnetic stirrer or magnetic mixer is a laboratory device that employs a rotating magnetic field to cause a stir bar (or flea) immersed in a liquid to spin very quickly, thus stirring it. The rotating field may be created either by a rotating magnet or a set of stationary electromagnets, placed beneath the vessel with the liquid. It is used in chemistry and biology as a convenient way to stir small volumes and where other forms of stirring, such as overhead stirrers and stirring rods, may not be viable.

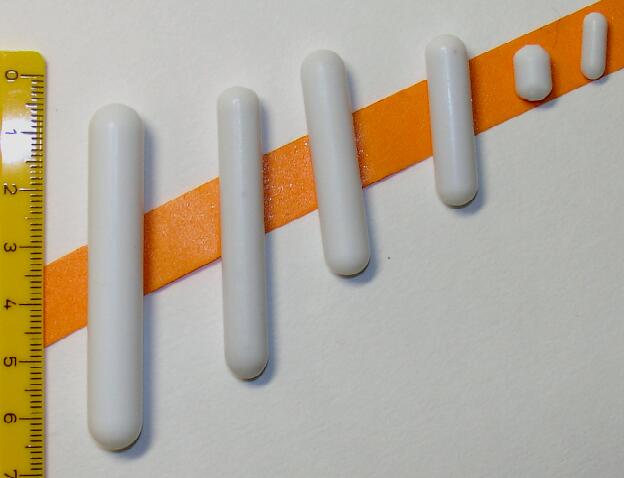

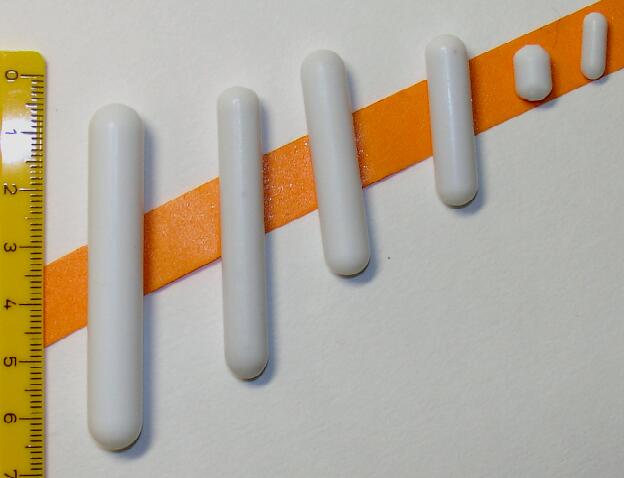

Structure for a magnetic stirrer.

A magnetic stirrer consists of a magnetic bar placed within the liquid which provides the stirring action. The stir bar's motion is driven by another rotating magnet or assembly of electromagnets in the stirrer device, beneath the vessel containing the liquid. Stir bars are typically coated in PTFE, or, less often, in glass; the coatings are intended to be chemically inert, not contaminating or reacting with the reaction mixture they are in. Glass may be viable as an alternative if PTFE is unsuitable due to high temperature or chemical attack. In dissolving metal reductions that use an alkali metal dissolved in a primary amine, PTFE may be attacked to some extent. Birch reductions (a common dissolving metal reduction) are often conducted in a glass vessel, thus indicating that a glass stir bar would likewise be compatible. Glass can be attacked by strong alkali (such as lye) depending on heat, exposure time, and concentration.

Application or usage for a magnetic stirrer.

Magnetic stirrers are often used in chemistry and biology, where they can be used to stir hermetically closed vessels or systems without the need for complicated rot seals. They are preferred over gear-driven motorized stirrers because they are quieter, more efficient, and have no moving external parts to break or wear out (other than the simple bar magnet itself). Magnetic stir bars work well in glass vessels commonly used for chemical reactions, as glass does not appreciably affect a magnetic field.

The limited size of the bar means that magnetic stirrers can only be used for relatively small experiments, of 4 litres or less. Stir bars also have difficulty in dealing with viscous liquids or thick suspensions. For larger volumes or more viscous liquids, some sort of mechanical stirring (e.g., an overhead stirrer) is typically needed. In synthetic chemistry, a combined magnetic stirrer/heater, equipped with a built-in temperature control mechanism and temperature probe, is commonly used with a heating bath (commonly oil, sand, or low-melting metal) or cooling bath (commonly water, ice, or an organic liquid mixed with liquid nitrogen or dry ice as coolant), allowing reactions vessels placed in the bath to be maintained at temperatures between approximately −120 and 250 °C (−184 and 482 °F).

A magnetic stirrer or magnetic mixer is a laboratory device that employs a rotating magnetic field to cause a stir bar (or flea) immersed in a liquid to spin very quickly, thus stirring it. The rotating field may be created either by a rotating magnet or a set of stationary electromagnets, placed beneath the vessel with the liquid. It is used in chemistry and biology as a convenient way to stir small volumes and where other forms of stirring, such as overhead stirrers and stirring rods, may not be viable.

Structure for a magnetic stirrer.

A magnetic stirrer consists of a magnetic bar placed within the liquid which provides the stirring action. The stir bar's motion is driven by another rotating magnet or assembly of electromagnets in the stirrer device, beneath the vessel containing the liquid. Stir bars are typically coated in PTFE, or, less often, in glass; the coatings are intended to be chemically inert, not contaminating or reacting with the reaction mixture they are in. Glass may be viable as an alternative if PTFE is unsuitable due to high temperature or chemical attack. In dissolving metal reductions that use an alkali metal dissolved in a primary amine, PTFE may be attacked to some extent. Birch reductions (a common dissolving metal reduction) are often conducted in a glass vessel, thus indicating that a glass stir bar would likewise be compatible. Glass can be attacked by strong alkali (such as lye) depending on heat, exposure time, and concentration.

Application or usage for a magnetic stirrer.

Magnetic stirrers are often used in chemistry and biology, where they can be used to stir hermetically closed vessels or systems without the need for complicated rot seals. They are preferred over gear-driven motorized stirrers because they are quieter, more efficient, and have no moving external parts to break or wear out (other than the simple bar magnet itself). Magnetic stir bars work well in glass vessels commonly used for chemical reactions, as glass does not appreciably affect a magnetic field.

The limited size of the bar means that magnetic stirrers can only be used for relatively small experiments, of 4 litres or less. Stir bars also have difficulty in dealing with viscous liquids or thick suspensions. For larger volumes or more viscous liquids, some sort of mechanical stirring (e.g., an overhead stirrer) is typically needed. In synthetic chemistry, a combined magnetic stirrer/heater, equipped with a built-in temperature control mechanism and temperature probe, is commonly used with a heating bath (commonly oil, sand, or low-melting metal) or cooling bath (commonly water, ice, or an organic liquid mixed with liquid nitrogen or dry ice as coolant), allowing reactions vessels placed in the bath to be maintained at temperatures between approximately −120 and 250 °C (−184 and 482 °F).