Laser Diffraction Particle Size Analyzer FAQ Guide : Essential Insights for Particle Size Distribution Operators And Buyers.

The FAQ Guide for laser diffraction particle size analyzer assists your successful in powder processing, application and research. It highlights the popularity of laser diffraction method due to their all - fast seed, high precision, good repeatability. The guide covers various particle size analysis methods, advantages and disadvantages. Additionally , it will guide you to choose the certain device reply on your requirement while save time and resources.

What Is The laser diffraction particle size analyzer ?

(LD)Laser diffraction analysis, also referred to as static light scattering, is the most widely method technique used for determining particle size distributions across a wide range of sizes, from hundreds of nanometers to several millimeters, aside from the conventional sieve analysis.

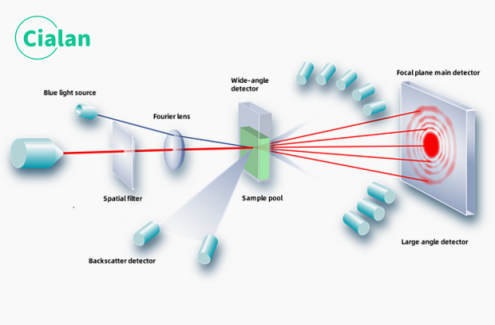

What Is The Working Principle Of Particle Size Analyzer?

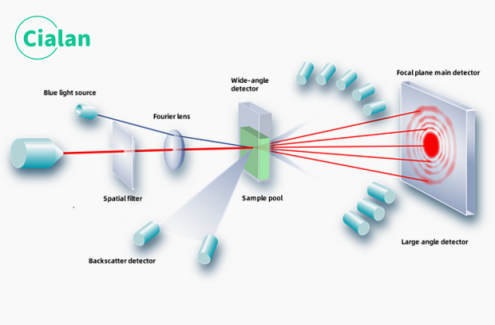

The laser particle sizer is based on the physical phenomenon that particles can make the laser scattering to test the particle size distribution. Since the laser has good monochromaticity and strong directionality, a parallel beam of laser light will irradiate to an infinite distance in an unobstructed infinite space, and there is very little dispersion in the propagation process.

When the beam encounters obstruction by a group of particles suspended in a liquid or gas stream, part of the light will be scattered or diffracted phenomenon, the size of the scattering or diffracting angle is related to the size of the particles, the larger the particles, the angle of the scattered or diffracted light produced is smaller; the smaller the particles, the angle of the scattered or diffracted produced is larger. Further studies have shown that the intensity of the scattered or diffracted light represents the number of particles of that particle size. In this way, by measuring the intensity of the scattered light at different angles, the particle size distribution of the sample can be obtained.

.jpg)

What Is Laser Diffraction(LD)?

The Laser Diffraction, also known as static light scattering, is one of the most advanced particle size measurement tools available. For laser diffraction particle size analysis, the principle is to determine the size and size distribution of particles by measuring the angle and intensity distribution of the diffracted light produced by the laser irradiating the particle sample.

What Are The Most Advanced Method To Analyze Particle Size?

Laser diffraction method (LD)

The Laser Diffraction method is one of the most advanced particle size measurement tools available. For laser diffraction particle size analysis, the principle is to determine the size and size distribution of particles by measuring the angle and intensity distribution of the diffracted light produced by the laser irradiating the particle sample.

Dynamic image analysis (DIA)

It takes detailed, high-definition snapshots of moving particles as they traverse the sensor area. The camera then processes these images to extract valuable data, including precise measurements of particle dimensions and morphology. With its broad dynamic range and exceptional precision, it enables rapid and reliable analysis of particles across a vast range of sizes and characteristics.

Dynamic light scattering method (DLS)

DLS is a well-established technique for measuring the average size and size distribution of particles in suspensions and emulsions.

Sedimentation method

The principle is based on the particles in the suspension system, the particles themselves gravity (or by centrifugal force), the buoyancy and viscous resistance to the balance of the three, and viscous force obeyed Stokes' law to the implementation of the measurement, when the particles in the suspension system with a constant rate of settling, and settling speed and size of the particle size proportional to the square.

Sieving method

This is a traditional method that is simple to operate and is suitable for analyzing larger particles by separating the particles by size through sieves of different mesh sizes.

.jpg)

What Is The Application Of laser diffraction particle size analyzer?

Laser scattering particle size analyzer is a precision instrument used to measure the size distribution of particles and is widely used in several industries. Below are some of the applications of particle sizers in different industries:

Pharmaceuticals: In the pharmaceutical industry, particle sizers are used to monitor the size and distribution of drug particles, which is essential to ensure the quality and efficacy of drugs.

Food: In food processing, particle size analyzers can analyze the particle size and distribution of food ingredients to help ensure the quality and taste of the food.

Coatings: In the coatings industry, particle sizers are used to measure the particle size and distribution of pigments in coatings to ensure uniformity and coverage.

Ink: In ink production, particle sizers are used to analyze particle size and distribution in ink to ensure ink print quality and smoothness.

Environmental monitoring: Particle sizers are used in environmental monitoring to measure the size distribution and number concentration of particles in atmospheric aerosols and other parameters, which is important for the study of air quality and environmental improvement.

Cement industry: In the process of cement production, controlling the size and distribution of cement particles is very critical to the performance of the product, and particle size meters play an important role here.

Abrasive industry: the particle size of abrasive directly affects its grinding effect, particle size meter can help producers control product quality and so on.

How Does a Laser Diffraction Particle Size Analyzer Work?

Preparation

Check the status of the instrument: check whether the appearance of the laser diffraction particle size analyzer is damaged and whether the parts are connected normally.

Choose suitable dispersing medium: according to the nature of the sample to be measured, choose a suitable dispersing medium (distilled water, ethanol).

Prepare the sample: Prepare the sample to be measured into a state suitable for laser diffraction particle size analyzer measurement. Grind the solid sample into powder form and make sure the particle size distribution of the sample is uniform. Liquid samples need to ensure that there are no air bubbles and impurities.

Instrument Setup

Turn on the instrument power: according to the requirements of the instrument manual, turn on the power switch of the laser diffraction particle size analyzer, wait for the instrument to warm up.

Setting parameters: according to the nature of the sample to be measured and measurement requirements, set the parameters of the laser diffraction particle size analyzer.

Sample Measurement

Add sample: Add the prepared sample into the sample cell of the laser diffraction particle size analyzer.

Start the measurement: according to the requirements of the instrument manual, start the measurement software SOP of the laser diffraction particle size analyzer.

Observe the measurement results: in the measurement process, you can observe the measurement results through the instrument's display.

Data processing and analysis

Data saving: after the completion of the measurement, the measurement results will be saved to the computer ( Excel, Word, Pdf ).

Data analysis: the use of laser diffraction particle size analyzer supporting data analysis software SOP, the measurement results are analyzed.

Particle size distribution curve: By analyzing the particle size distribution curve, you can understand the proportion of different particle sizes in the sample.

Eigenvalues: d (0.1), d (0.5), d (0.9) indicate the particle size when the cumulative particle size distribution in the sample reaches 10%, 50%, 90% respectively. By analyzing the eigenvalues, it is possible to understand the range of particle size distribution and the median particle size of the sample.

Average particle size and standard deviation: The mean particle size is the average of all particle sizes in the sample, and the standard deviation is a parameter that describes the degree of dispersion of the particle size distribution. Through the analysis, you can understand the uniformity of the particle size distribution of the sample.

End of measurement

Clean the instrument: after the completion of the measurement, clean the sample cell and components of the laser diffraction particle size analyzer in a timely manner, to avoid the sample residue on the next measurement results have an impact.

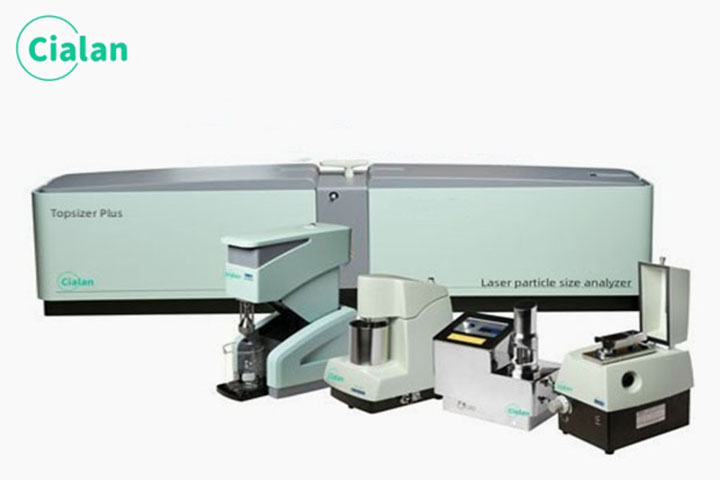

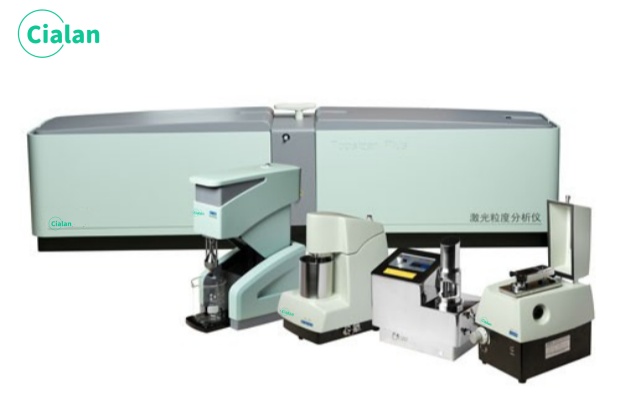

How To Choose a laser diffraction particle size analyzer?

Measuring Principle: laser granulometry particle size analyzer is a widely used particle size testing instrument, which measures the size and distribution of particles by the principle of laser diffraction or scattering. This method of testing is fast and accurate, and is suitable for a variety of fields, such as powder coatings, lithium battery materials, cement, abrasives, pharmaceuticals, pesticides, food, chemicals and so on.

Laser selection: The laser is one of the most important components of a laser diffraction particle size analyzer. HE - NE lasers usually outperform semiconductor lasers and are more cost effective. Semiconductor lasers may suffer from poor unidirectionality, which may affect the stability of the test results. Therefore, if budget allows, it is recommended to choose a laser with

HE - NE lasers are recommended if budget allows.

Photodetectors: The type of photodetector has an impact on the accuracy of the test. Half-ring detectors are able to achieve high accuracy with a small number of channels, and can be used temporarily to merge rings in case of breakage, which has a low impact on the test results. Dot-matrix detectors are of an older type and are less used nowadays.

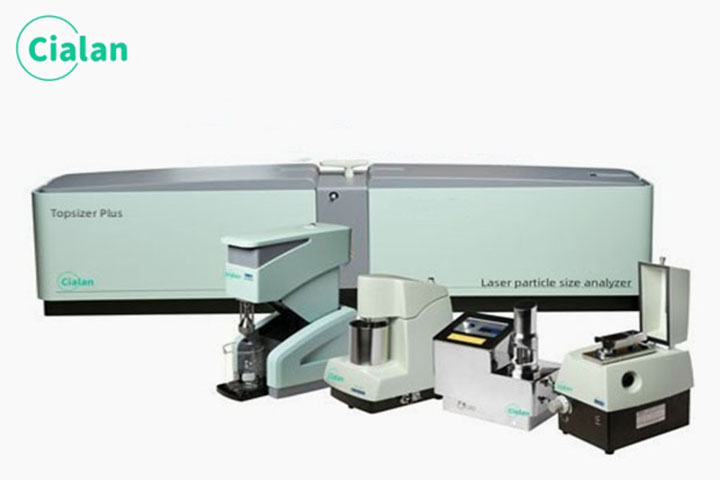

Measurement range: Different particle sizers may be suitable for different measurement ranges. For example, the Cialan Topsizer plus laser diffraction particle size analyzer can measure in the nanometer to millimeter size range and is suitable for particle size distribution testing of wet and dry dispersions.

Technology advancement: Choosing a brand of particle sizer with advanced technology and patents can ensure the technical performance and reliability of the equipment. For example, the Cialan particle size analyzer company has mastered a number of cutting-edge technologies in particle size testing and has applied them to our instruments, resulting in leading-edge technical performance.

Application: Choose the appropriate particle size analyzer for your specific application. Different industries have different requirements for particle size, so you need to choose equipment that can meet specific industry standards.

Brand and after-sales service: Choose a well-known brand of particle sizer manufacturers can get more reliable product quality and more perfect after-sales service.

Budget: Choose the right particle size analyzer according to your budget. High-end equipment is usually more expensive, but offers better performance and accuracy.

Ease of operation: Consider how easy the equipment is to operate, whether specialized operators are required, and whether there is a user interface that is easy to understand and operate. Maintenance Costs: Understand the maintenance needs and costs of the equipment, including consumable replacement, periodic calibration, etc.

How To Determine Particle Size Distribution(PSD)?

When a light beam is blocked by particles, part of the light will be scattered. The propagation direction of the scattered light will form an angle with the propagation direction of the main light beam. Both scattering theory and experimental results tell us that the size of the scattering angle is related to the size of the particle.

The larger the particle, the smaller the angle of the scattered light; the smaller the particle, the larger the angle of the scattered light. Further research shows that the intensity of the scattered light represents the number of particles of that size. In this way, by measuring the intensity of the scattered light at different angles, the particle size distribution of the sample can be obtained.

How To Interpret Particle Size Analyzer Results?

To correctly understand the data results of the laser particle size analyzer, you need to pay attention to the following key aspects:

1. Particle size distribution curve:

This curve shows the percentage or volume distribution of particles of different particle sizes. Common forms include cumulative percentage distribution and frequency distribution.

The shape and trend of the curve can intuitively reflect the particle size range and distribution of the sample. For example, the steeper the curve, the more concentrated the particle size; conversely, the flatter the curve, the greater the difference in particle size.

2. Average particle size:

The average particle size is an important indicator to describe the overall particle size of the sample, usually expressed as D10, D50, D90, etc.

D50 refers to the particle size value corresponding to the cumulative distribution percentage reaching 50%, that is, 50% of the particles have a particle size larger than this value and 50% are smaller than this value. D10 and D90 indicate that 10% and 90% of the particles have a particle size smaller than this value.

3. Particle size distribution width:

Reflects the degree of dispersion of particle size, usually evaluated by calculating the standard deviation or relative width.

The smaller the distribution width, the more uniform the particle size; the larger the distribution width, the greater the difference in particle size.

4. Outlier analysis:

In the distribution curve, there may be outliers or peaks, which require further analysis to identify possible special particle types or contaminants.

5. Trend analysis:

Comparing the test results of different samples or batches helps to find the differences and changing trends between samples and evaluate the stability and consistency of samples.

6. Application evaluation:

Combining specific application requirements and sample characteristics for comprehensive analysis, it provides an important reference for product development, production process control and quality control.

How Does Laser Diffraction Measure Particle Size?

Laser diffraction measures particle size distribution by measuring the change in the angle of scattered light when a laser beam passes through a dispersed sample of particles. Larger particles scatter light at smaller angles, while smaller particles scatter light at larger angles, allowing the size of the particles to be determined.

Which Detector Is Used In a Particle Size Analyzer?

The photodetector is a specially customized imported photoelectric detector, which ensures that the instrument has high resolution and sensitivity. Combined with the blue light scattering signal, it realizes the seamless reception of scattered light energy signals in the full angle range of space, effectively ensuring the comprehensive and accurate acquisition of particle scattered light energy information.

What Is The Cost Of Particle Size Analysis?

Laser particle size distribution analyzer system typically range from $13,000 to $105,000, depending on its application areas, features, measurement range, specifications, and manufacturers. For seeking a cost-effective option, you can ask your preferred laser particle size analyzer manufacturer to provide a model and quotation according to your requirements.

What Is Particle And Particle Size Representation?

Particle and size representation is a set of parameters that describe the size and shape of particles in a granular system. These parameters are important for many industrial processes and scientific research because the size and shape of the particles affect the properties, flow, reactivity, etc. of the material.

In order to accurately describe and control particulate systems, a variety of methods and instruments are often used to measure these parameters, such as laser diffraction particle size analyzers. In many industrial fields, such as pharmaceuticals, food, chemicals, materials science, etc., particle and size representation are critical because they have a direct impact on the quality, stability, and performance of the product.

What Is The Measurement Points Of Particle Size Distribution?

For particle size representation and quality control, you need to do:

Science of Sampling, Science of Dispersion, Accuracy of Testing Instruments, Resolving Power of Test Instruments.

How To Ensure The Accuracy Of laser diffraction particle size analyzer Analysis Data Results?

The authenticity of the measurement is controlled according to international standards, and the instrument is validated with a known sample or sample mixture. Linear analysis of known content fractions is used to assess the true level of instrumentation and methodology at different particle size bands.

.jpg)

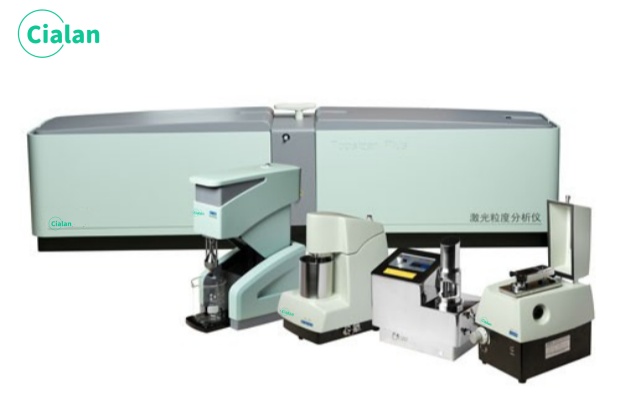

What Is The Advantages And Disadvantages Laser Diffraction Particle Size Analyzer?

Advantages :

Fast speed: laser diffraction particle size analyzer can complete the particle size analysis of the sample in minute, which greatly improves the working efficiency.

High precision: laser diffraction particle size analyzer adopts advanced optical technology and data analysis method, which can accurately measure the particle size of particles.

Good Repeatability: The measurement results of the laser particle size meter have good repeatability, which means that under the same experimental conditions, the same sample is measured several times, and the difference between the results is small.

Non-Contact Measurement: The laser diffraction particle size analyzer does not come into direct contact with the sample during the measurement process, avoiding contamination and damage to the sample.

Easy to operate: laser diffraction particle size analyzers are usually characterized by a high degree of automation and a user-friendly interface, making it easy for users to master the use of the instrument.

Versatility: The method can characterize both liquid particulate samples as well as fine powders, suspensions or emulsions.

Large number of samples: The laser particle size analyzer can characterize a wide range and a large number of particulate samples.

Disadvantages :

Sampling process is not quantitative: the laser diffraction particle size analyzer is not quantitative in the sampling process, which may lead to some randomness and uncertainty in the analysis results of some sedimentary samples, and the analysis results are prone to human error.

Higher requirements for samples: laser diffraction particle size analyzer requires higher dispersion of samples, if the samples are not sufficiently dispersed during the measurement process, it will lead to inaccurate measurement results. In addition, for some easily agglomerated samples, special dispersion methods are required, increasing the complexity of the experiment.

Extremely low or high concentrations: The laser particle sizer has limitations in analyzing samples with extremely low or high concentrations, and it also struggles to accurately measure the size of extremely fine particles.

Hard for large particles: Additionally when analyzing larger particles, and it is unable to provide information about the shape of particles, particularly those that are non-spherical.

Furthermore, samples with multiple particle sizes can lead to inaccurate results, and the device is not capable of continuously tracking particle counts over a specified time frame.

.jpg)

What Are The Advantages And Disadvantages of Different Particle Sizing Methods?

What Is The Difference Between Laser Diffraction(LD) And Dynamic Light Scattering(DLS)?

Principle:

Laser diffraction(LD): Laser diffraction uses light scattering caused by the interference of light wave propagation caused by the interaction between light waves and particles to determine particle size and particle size distribution.

Dynamic light scattering(DLS): The principle of dynamic light scattering utilizes the fluctuation of scattered light intensity caused by Brownian motion of particles in the submicron range.

Measurement range:

Laser diffraction(LD): Mainly suitable for the measurement of larger particles, and can characterize particle systems ranging from 0.5μm to 3500μm.

Dynamic light scattering(DLS): Usually used for the measurement of particles in the submicron range.

Measurement object:

Laser diffraction(LD): It can be used to measure the particle size and particle size distribution of various particle systems, and is widely used in precision equipment, energy, environment and medical fields.

Dynamic light scattering(DLS): It is widely used in biology, chemistry and other fields.

Measurement characteristics:

Laser diffraction(LD): The measurement time is relatively short, and the time change from bubble generation to bubble disappearance can be observed in a short time

Dynamic light scattering(DLS): The fluctuation of scattered light intensity caused by Brownian motion is used to measure particle size, which is more accurate for the measurement of nano-scale particles.

Data processing:

Laser diffraction(LD): usually needs to be corrected based on Mie scattering theory. By calibrating with standard particles, the number concentration or volume concentration can be determined.

Dynamic scattering(DLS): complex data analysis of the fluctuation of scattered light intensity is required to determine the particle size information. Usually professional software is required for data processing to improve the accuracy and reliability of the measurement.

What Does D10 D50 D90 Mean In Particle Size Distribution?

In the PSD (particle size distribution) test, D10, D50, and D90 are important parameters used to describe the particle size distribution:

D10: Indicates that in the sample, 10% of the particles have a particle size smaller than this value. It reflects the content of smaller particles in the sample and is usually used to indicate the fine end particle size index of the sample.

D50: Also known as the median diameter or median particle size, it refers to the particle size corresponding to the cumulative particle size distribution of 50% in the sample. D50 indicates that 50% of the particles have a particle size larger than this value and 50% of the particles have a particle size smaller than this value, and is often used to indicate the average particle size of the powder.

D90: Indicates the particle size corresponding to the cumulative particle size distribution of 90% in the sample. It reflects the content of larger particles in the sample and is usually used to indicate the coarse end particle size index of the sample.

What Does D[3,2]、D[4,3]Mean In Particle Size?

D[4,3] and D[3,2], represent volume-weighted mean diameter and surface area-weighted mean diameter, respectively, and are utilized to facilitate comparisons between various analytical methods.

What Is The laser diffraction particle size analyzer ?

(LD)Laser diffraction analysis, also referred to as static light scattering, is the most widely method technique used for determining particle size distributions across a wide range of sizes, from hundreds of nanometers to several millimeters, aside from the conventional sieve analysis.

What Is The Working Principle Of Particle Size Analyzer?

The laser particle sizer is based on the physical phenomenon that particles can make the laser scattering to test the particle size distribution. Since the laser has good monochromaticity and strong directionality, a parallel beam of laser light will irradiate to an infinite distance in an unobstructed infinite space, and there is very little dispersion in the propagation process.

When the beam encounters obstruction by a group of particles suspended in a liquid or gas stream, part of the light will be scattered or diffracted phenomenon, the size of the scattering or diffracting angle is related to the size of the particles, the larger the particles, the angle of the scattered or diffracted light produced is smaller; the smaller the particles, the angle of the scattered or diffracted produced is larger. Further studies have shown that the intensity of the scattered or diffracted light represents the number of particles of that particle size. In this way, by measuring the intensity of the scattered light at different angles, the particle size distribution of the sample can be obtained.

.jpg)

What Is Laser Diffraction(LD)?

The Laser Diffraction, also known as static light scattering, is one of the most advanced particle size measurement tools available. For laser diffraction particle size analysis, the principle is to determine the size and size distribution of particles by measuring the angle and intensity distribution of the diffracted light produced by the laser irradiating the particle sample.

What Are The Most Advanced Method To Analyze Particle Size?

Laser diffraction method (LD)

The Laser Diffraction method is one of the most advanced particle size measurement tools available. For laser diffraction particle size analysis, the principle is to determine the size and size distribution of particles by measuring the angle and intensity distribution of the diffracted light produced by the laser irradiating the particle sample.

Dynamic image analysis (DIA)

It takes detailed, high-definition snapshots of moving particles as they traverse the sensor area. The camera then processes these images to extract valuable data, including precise measurements of particle dimensions and morphology. With its broad dynamic range and exceptional precision, it enables rapid and reliable analysis of particles across a vast range of sizes and characteristics.

Dynamic light scattering method (DLS)

DLS is a well-established technique for measuring the average size and size distribution of particles in suspensions and emulsions.

Sedimentation method

The principle is based on the particles in the suspension system, the particles themselves gravity (or by centrifugal force), the buoyancy and viscous resistance to the balance of the three, and viscous force obeyed Stokes' law to the implementation of the measurement, when the particles in the suspension system with a constant rate of settling, and settling speed and size of the particle size proportional to the square.

Sieving method

This is a traditional method that is simple to operate and is suitable for analyzing larger particles by separating the particles by size through sieves of different mesh sizes.

.jpg)

What Is The Application Of laser diffraction particle size analyzer?

Laser scattering particle size analyzer is a precision instrument used to measure the size distribution of particles and is widely used in several industries. Below are some of the applications of particle sizers in different industries:

Pharmaceuticals: In the pharmaceutical industry, particle sizers are used to monitor the size and distribution of drug particles, which is essential to ensure the quality and efficacy of drugs.

Food: In food processing, particle size analyzers can analyze the particle size and distribution of food ingredients to help ensure the quality and taste of the food.

Coatings: In the coatings industry, particle sizers are used to measure the particle size and distribution of pigments in coatings to ensure uniformity and coverage.

Ink: In ink production, particle sizers are used to analyze particle size and distribution in ink to ensure ink print quality and smoothness.

Environmental monitoring: Particle sizers are used in environmental monitoring to measure the size distribution and number concentration of particles in atmospheric aerosols and other parameters, which is important for the study of air quality and environmental improvement.

Cement industry: In the process of cement production, controlling the size and distribution of cement particles is very critical to the performance of the product, and particle size meters play an important role here.

Abrasive industry: the particle size of abrasive directly affects its grinding effect, particle size meter can help producers control product quality and so on.

How Does a Laser Diffraction Particle Size Analyzer Work?

Preparation

Check the status of the instrument: check whether the appearance of the laser diffraction particle size analyzer is damaged and whether the parts are connected normally.

Choose suitable dispersing medium: according to the nature of the sample to be measured, choose a suitable dispersing medium (distilled water, ethanol).

Prepare the sample: Prepare the sample to be measured into a state suitable for laser diffraction particle size analyzer measurement. Grind the solid sample into powder form and make sure the particle size distribution of the sample is uniform. Liquid samples need to ensure that there are no air bubbles and impurities.

Instrument Setup

Turn on the instrument power: according to the requirements of the instrument manual, turn on the power switch of the laser diffraction particle size analyzer, wait for the instrument to warm up.

Setting parameters: according to the nature of the sample to be measured and measurement requirements, set the parameters of the laser diffraction particle size analyzer.

Sample Measurement

Add sample: Add the prepared sample into the sample cell of the laser diffraction particle size analyzer.

Start the measurement: according to the requirements of the instrument manual, start the measurement software SOP of the laser diffraction particle size analyzer.

Observe the measurement results: in the measurement process, you can observe the measurement results through the instrument's display.

Data processing and analysis

Data saving: after the completion of the measurement, the measurement results will be saved to the computer ( Excel, Word, Pdf ).

Data analysis: the use of laser diffraction particle size analyzer supporting data analysis software SOP, the measurement results are analyzed.

Particle size distribution curve: By analyzing the particle size distribution curve, you can understand the proportion of different particle sizes in the sample.

Eigenvalues: d (0.1), d (0.5), d (0.9) indicate the particle size when the cumulative particle size distribution in the sample reaches 10%, 50%, 90% respectively. By analyzing the eigenvalues, it is possible to understand the range of particle size distribution and the median particle size of the sample.

Average particle size and standard deviation: The mean particle size is the average of all particle sizes in the sample, and the standard deviation is a parameter that describes the degree of dispersion of the particle size distribution. Through the analysis, you can understand the uniformity of the particle size distribution of the sample.

End of measurement

Clean the instrument: after the completion of the measurement, clean the sample cell and components of the laser diffraction particle size analyzer in a timely manner, to avoid the sample residue on the next measurement results have an impact.

How To Choose a laser diffraction particle size analyzer?

Measuring Principle: laser granulometry particle size analyzer is a widely used particle size testing instrument, which measures the size and distribution of particles by the principle of laser diffraction or scattering. This method of testing is fast and accurate, and is suitable for a variety of fields, such as powder coatings, lithium battery materials, cement, abrasives, pharmaceuticals, pesticides, food, chemicals and so on.

Laser selection: The laser is one of the most important components of a laser diffraction particle size analyzer. HE - NE lasers usually outperform semiconductor lasers and are more cost effective. Semiconductor lasers may suffer from poor unidirectionality, which may affect the stability of the test results. Therefore, if budget allows, it is recommended to choose a laser with

HE - NE lasers are recommended if budget allows.

Photodetectors: The type of photodetector has an impact on the accuracy of the test. Half-ring detectors are able to achieve high accuracy with a small number of channels, and can be used temporarily to merge rings in case of breakage, which has a low impact on the test results. Dot-matrix detectors are of an older type and are less used nowadays.

Measurement range: Different particle sizers may be suitable for different measurement ranges. For example, the Cialan Topsizer plus laser diffraction particle size analyzer can measure in the nanometer to millimeter size range and is suitable for particle size distribution testing of wet and dry dispersions.

Technology advancement: Choosing a brand of particle sizer with advanced technology and patents can ensure the technical performance and reliability of the equipment. For example, the Cialan particle size analyzer company has mastered a number of cutting-edge technologies in particle size testing and has applied them to our instruments, resulting in leading-edge technical performance.

Application: Choose the appropriate particle size analyzer for your specific application. Different industries have different requirements for particle size, so you need to choose equipment that can meet specific industry standards.

Brand and after-sales service: Choose a well-known brand of particle sizer manufacturers can get more reliable product quality and more perfect after-sales service.

Budget: Choose the right particle size analyzer according to your budget. High-end equipment is usually more expensive, but offers better performance and accuracy.

Ease of operation: Consider how easy the equipment is to operate, whether specialized operators are required, and whether there is a user interface that is easy to understand and operate. Maintenance Costs: Understand the maintenance needs and costs of the equipment, including consumable replacement, periodic calibration, etc.

How To Determine Particle Size Distribution(PSD)?

When a light beam is blocked by particles, part of the light will be scattered. The propagation direction of the scattered light will form an angle with the propagation direction of the main light beam. Both scattering theory and experimental results tell us that the size of the scattering angle is related to the size of the particle.

The larger the particle, the smaller the angle of the scattered light; the smaller the particle, the larger the angle of the scattered light. Further research shows that the intensity of the scattered light represents the number of particles of that size. In this way, by measuring the intensity of the scattered light at different angles, the particle size distribution of the sample can be obtained.

How To Interpret Particle Size Analyzer Results?

To correctly understand the data results of the laser particle size analyzer, you need to pay attention to the following key aspects:

1. Particle size distribution curve:

This curve shows the percentage or volume distribution of particles of different particle sizes. Common forms include cumulative percentage distribution and frequency distribution.

The shape and trend of the curve can intuitively reflect the particle size range and distribution of the sample. For example, the steeper the curve, the more concentrated the particle size; conversely, the flatter the curve, the greater the difference in particle size.

2. Average particle size:

The average particle size is an important indicator to describe the overall particle size of the sample, usually expressed as D10, D50, D90, etc.

D50 refers to the particle size value corresponding to the cumulative distribution percentage reaching 50%, that is, 50% of the particles have a particle size larger than this value and 50% are smaller than this value. D10 and D90 indicate that 10% and 90% of the particles have a particle size smaller than this value.

3. Particle size distribution width:

Reflects the degree of dispersion of particle size, usually evaluated by calculating the standard deviation or relative width.

The smaller the distribution width, the more uniform the particle size; the larger the distribution width, the greater the difference in particle size.

4. Outlier analysis:

In the distribution curve, there may be outliers or peaks, which require further analysis to identify possible special particle types or contaminants.

5. Trend analysis:

Comparing the test results of different samples or batches helps to find the differences and changing trends between samples and evaluate the stability and consistency of samples.

6. Application evaluation:

Combining specific application requirements and sample characteristics for comprehensive analysis, it provides an important reference for product development, production process control and quality control.

How Does Laser Diffraction Measure Particle Size?

Laser diffraction measures particle size distribution by measuring the change in the angle of scattered light when a laser beam passes through a dispersed sample of particles. Larger particles scatter light at smaller angles, while smaller particles scatter light at larger angles, allowing the size of the particles to be determined.

Which Detector Is Used In a Particle Size Analyzer?

The photodetector is a specially customized imported photoelectric detector, which ensures that the instrument has high resolution and sensitivity. Combined with the blue light scattering signal, it realizes the seamless reception of scattered light energy signals in the full angle range of space, effectively ensuring the comprehensive and accurate acquisition of particle scattered light energy information.

What Is The Cost Of Particle Size Analysis?

Laser particle size distribution analyzer system typically range from $13,000 to $105,000, depending on its application areas, features, measurement range, specifications, and manufacturers. For seeking a cost-effective option, you can ask your preferred laser particle size analyzer manufacturer to provide a model and quotation according to your requirements.

What Is Particle And Particle Size Representation?

Particle and size representation is a set of parameters that describe the size and shape of particles in a granular system. These parameters are important for many industrial processes and scientific research because the size and shape of the particles affect the properties, flow, reactivity, etc. of the material.

In order to accurately describe and control particulate systems, a variety of methods and instruments are often used to measure these parameters, such as laser diffraction particle size analyzers. In many industrial fields, such as pharmaceuticals, food, chemicals, materials science, etc., particle and size representation are critical because they have a direct impact on the quality, stability, and performance of the product.

What Is The Measurement Points Of Particle Size Distribution?

For particle size representation and quality control, you need to do:

Science of Sampling, Science of Dispersion, Accuracy of Testing Instruments, Resolving Power of Test Instruments.

How To Ensure The Accuracy Of laser diffraction particle size analyzer Analysis Data Results?

The authenticity of the measurement is controlled according to international standards, and the instrument is validated with a known sample or sample mixture. Linear analysis of known content fractions is used to assess the true level of instrumentation and methodology at different particle size bands.

.jpg)

What Is The Advantages And Disadvantages Laser Diffraction Particle Size Analyzer?

Advantages :

Fast speed: laser diffraction particle size analyzer can complete the particle size analysis of the sample in minute, which greatly improves the working efficiency.

High precision: laser diffraction particle size analyzer adopts advanced optical technology and data analysis method, which can accurately measure the particle size of particles.

Good Repeatability: The measurement results of the laser particle size meter have good repeatability, which means that under the same experimental conditions, the same sample is measured several times, and the difference between the results is small.

Non-Contact Measurement: The laser diffraction particle size analyzer does not come into direct contact with the sample during the measurement process, avoiding contamination and damage to the sample.

Easy to operate: laser diffraction particle size analyzers are usually characterized by a high degree of automation and a user-friendly interface, making it easy for users to master the use of the instrument.

Versatility: The method can characterize both liquid particulate samples as well as fine powders, suspensions or emulsions.

Large number of samples: The laser particle size analyzer can characterize a wide range and a large number of particulate samples.

Disadvantages :

Sampling process is not quantitative: the laser diffraction particle size analyzer is not quantitative in the sampling process, which may lead to some randomness and uncertainty in the analysis results of some sedimentary samples, and the analysis results are prone to human error.

Higher requirements for samples: laser diffraction particle size analyzer requires higher dispersion of samples, if the samples are not sufficiently dispersed during the measurement process, it will lead to inaccurate measurement results. In addition, for some easily agglomerated samples, special dispersion methods are required, increasing the complexity of the experiment.

Extremely low or high concentrations: The laser particle sizer has limitations in analyzing samples with extremely low or high concentrations, and it also struggles to accurately measure the size of extremely fine particles.

Hard for large particles: Additionally when analyzing larger particles, and it is unable to provide information about the shape of particles, particularly those that are non-spherical.

Furthermore, samples with multiple particle sizes can lead to inaccurate results, and the device is not capable of continuously tracking particle counts over a specified time frame.

.jpg)

What Are The Advantages And Disadvantages of Different Particle Sizing Methods?

| Laser diffraction method |

A: The device offers straightforward operation, quick analysis, a broad range of testing capabilities, precise and consistent results, a choice of sampling methods. |

| D: The effectiveness of this method is limited for bimodal distributions with closely spaced peaks, making it less ideal for nanoparticle analysis. The accuracy of test results can be compromised by the distribution pattern, while the high cost of the instrument and its limited resolution further hinder its performance. | |

| Dynamic image analysis |

A: Straightforward, user-friendly, and allows for morphological examination. Ideal for analyzing samples with a large particle size range. |

| D: A lack of representative accuracy, inapplicability to samples with diverse particle sizes, and an inability to analyze extremely small particles. | |

| Dynamic light scattering method |

A: Offers a broad measurement spectrum. Provides quick analysis. User-friendly. Highly effective for nanoparticles. |

| D: Potential for measurement inaccuracies with particles of various sizes. Only compatible with see-through samples. | |

| Sedimentation method |

A: The instrument can operate over a wide range of conditions, allowing for continuous operation and providing cost savings. It offers high accuracy and consistency in results, accommodating various sizes of test particles. |

| D: Long test time, complicated operation, insufficient measurement of non-spherical particles. | |

| Sieving method |

A: simple, low cost, suitable for particles >38μm. |

| D: Not suitable for small particles (<38μm). Human factors and mesh deformation have a significant impact on the results. |

|

| Coulter counter method |

A: Easy to operate, analyze speed block, high precision, good repeatability |

| D: Narrow size range, not suitable for small particles and particles with wide size distribution, need to change the aperture according to the size of the particles, need a conductive medium. | |

| Electron microscope |

A: Suitable for testing ultrafine particles or nanoparticles, high resolution. |

| D: Few samples, low representativeness, expensive instrument. | |

| Photo-resist method |

A: Rapid and straightforward testing, the ability to detect particles in liquids or gases at very low levels, precise particle counting capabilities, and high-definition analysis. |

| D: Not effective for analyzing samples with dimensions less than 1 micron. | |

| Ultrasonic method |

A:No need to dilute, can directly test the high concentration of liquid. |

| D: Low resolution, measurement error for particles with wide size distribution. |

What Is The Difference Between Laser Diffraction(LD) And Dynamic Light Scattering(DLS)?

Principle:

Laser diffraction(LD): Laser diffraction uses light scattering caused by the interference of light wave propagation caused by the interaction between light waves and particles to determine particle size and particle size distribution.

Dynamic light scattering(DLS): The principle of dynamic light scattering utilizes the fluctuation of scattered light intensity caused by Brownian motion of particles in the submicron range.

Measurement range:

Laser diffraction(LD): Mainly suitable for the measurement of larger particles, and can characterize particle systems ranging from 0.5μm to 3500μm.

Dynamic light scattering(DLS): Usually used for the measurement of particles in the submicron range.

Measurement object:

Laser diffraction(LD): It can be used to measure the particle size and particle size distribution of various particle systems, and is widely used in precision equipment, energy, environment and medical fields.

Dynamic light scattering(DLS): It is widely used in biology, chemistry and other fields.

Measurement characteristics:

Laser diffraction(LD): The measurement time is relatively short, and the time change from bubble generation to bubble disappearance can be observed in a short time

Dynamic light scattering(DLS): The fluctuation of scattered light intensity caused by Brownian motion is used to measure particle size, which is more accurate for the measurement of nano-scale particles.

Data processing:

Laser diffraction(LD): usually needs to be corrected based on Mie scattering theory. By calibrating with standard particles, the number concentration or volume concentration can be determined.

Dynamic scattering(DLS): complex data analysis of the fluctuation of scattered light intensity is required to determine the particle size information. Usually professional software is required for data processing to improve the accuracy and reliability of the measurement.

What Does D10 D50 D90 Mean In Particle Size Distribution?

In the PSD (particle size distribution) test, D10, D50, and D90 are important parameters used to describe the particle size distribution:

D10: Indicates that in the sample, 10% of the particles have a particle size smaller than this value. It reflects the content of smaller particles in the sample and is usually used to indicate the fine end particle size index of the sample.

D50: Also known as the median diameter or median particle size, it refers to the particle size corresponding to the cumulative particle size distribution of 50% in the sample. D50 indicates that 50% of the particles have a particle size larger than this value and 50% of the particles have a particle size smaller than this value, and is often used to indicate the average particle size of the powder.

D90: Indicates the particle size corresponding to the cumulative particle size distribution of 90% in the sample. It reflects the content of larger particles in the sample and is usually used to indicate the coarse end particle size index of the sample.

What Does D[3,2]、D[4,3]Mean In Particle Size?

D[4,3] and D[3,2], represent volume-weighted mean diameter and surface area-weighted mean diameter, respectively, and are utilized to facilitate comparisons between various analytical methods.