Maintenance of electric centrifugal divider.

Maintenance of electric centrifugal divider.

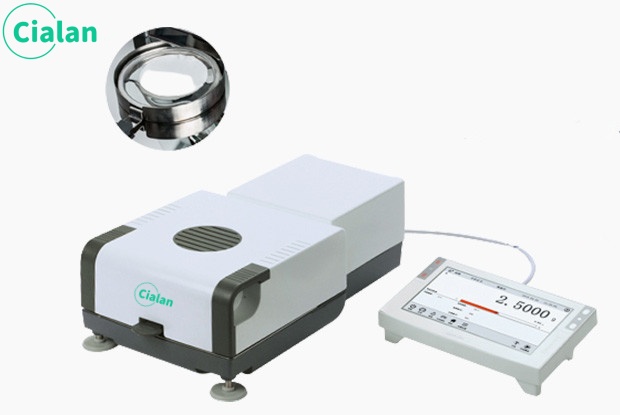

The electric centrifugal divider iare widely used in medical, scientific research, biopharmaceutical and other fields, and are common laboratory equipment. In order to ensure the stability and reliability of the sample divider, regular maintenance is essential. Mainly includes cleaning and disinfection, parts inspection and replacement, daily use precautions, etc. Correct maintenance can extend the service life of the machine and ensure its normal operation and sample processing results.

Cleaning and Disinfection

Cleaning steps: Disconnect the power supply and remove the centrifuge cup, centrifuge rotor and other removable parts. Then clean the surface of the parts with warm water and neutral detergent. Do not use acidic or alkaline detergents. Dry the parts with a clean cloth and place them in a ventilated and dry place to dry.

Disinfection method: For specific samples or experimental requirements, high-temperature and high-pressure disinfection, ultraviolet disinfection or chemical disinfection methods can be used for disinfection. When disinfecting, ensure that the electric centrifugal sampler is dry to avoid damage to electronic and mechanical components.

Parts inspection and replacement

Rotor inspection: Check the balance status of the rotor regularly. If any imbalance is found, replace the rotor with a new one in time. In addition, it is necessary to check whether the rotor bearings are operating normally. If abnormal noise or increased friction is found, the bearings should be cleaned or replaced in time.

Power supply system: Check whether the power line is damaged or aging, and replace it in time if there is any problem; also check whether the contact between the power plug and the socket is good to prevent unstable current from causing equipment failure.

Control panel and display screen: Regularly check the working status of the control panel and display screen. If there are any abnormalities or malfunctions, contact professional maintenance personnel for repair or replacement.

Summary

The maintenance of electric centrifugal sample dividers is crucial to extending the life of the equipment and ensuring the accuracy of experiments. Through correct cleaning and disinfection, parts inspection and replacement, daily use precautions and other maintenance methods, we can ensure that the machine operates normally and the sample processing effect is good. Scientific and reasonable maintenance can not only improve laboratory work efficiency, but also reduce the risk of failures and accidents and ensure the safe operation of the laboratory.

The electric centrifugal divider iare widely used in medical, scientific research, biopharmaceutical and other fields, and are common laboratory equipment. In order to ensure the stability and reliability of the sample divider, regular maintenance is essential. Mainly includes cleaning and disinfection, parts inspection and replacement, daily use precautions, etc. Correct maintenance can extend the service life of the machine and ensure its normal operation and sample processing results.

Cleaning and Disinfection

Cleaning steps: Disconnect the power supply and remove the centrifuge cup, centrifuge rotor and other removable parts. Then clean the surface of the parts with warm water and neutral detergent. Do not use acidic or alkaline detergents. Dry the parts with a clean cloth and place them in a ventilated and dry place to dry.

Disinfection method: For specific samples or experimental requirements, high-temperature and high-pressure disinfection, ultraviolet disinfection or chemical disinfection methods can be used for disinfection. When disinfecting, ensure that the electric centrifugal sampler is dry to avoid damage to electronic and mechanical components.

Parts inspection and replacement

Rotor inspection: Check the balance status of the rotor regularly. If any imbalance is found, replace the rotor with a new one in time. In addition, it is necessary to check whether the rotor bearings are operating normally. If abnormal noise or increased friction is found, the bearings should be cleaned or replaced in time.

Power supply system: Check whether the power line is damaged or aging, and replace it in time if there is any problem; also check whether the contact between the power plug and the socket is good to prevent unstable current from causing equipment failure.

Control panel and display screen: Regularly check the working status of the control panel and display screen. If there are any abnormalities or malfunctions, contact professional maintenance personnel for repair or replacement.

Summary

The maintenance of electric centrifugal sample dividers is crucial to extending the life of the equipment and ensuring the accuracy of experiments. Through correct cleaning and disinfection, parts inspection and replacement, daily use precautions and other maintenance methods, we can ensure that the machine operates normally and the sample processing effect is good. Scientific and reasonable maintenance can not only improve laboratory work efficiency, but also reduce the risk of failures and accidents and ensure the safe operation of the laboratory.