LS-609 Particle size analyzer escorts coating industry to green carbon.

Cialan Instrument in coating industry.

Cialan is deeply involved in the coatings industry and always pays attention to understanding market trends and customer needs. For the coatings industry, it has formed a matrix of related supporting products and particle size detection solutions such as wet laser particle size analyzers, dry laser particle size analyzers, and nanoparticle size potential analyzers. Make contributions to the best of our ability to improve the quality and efficiency of the industry.

Wet dispersion method.

Wet testing is a commonly used testing method in the coating industry for water-based acrylic coatings, water-based coatings, powder coatings, etc. Since water is a good conductor of sound waves and a universal solvent, additional dispersion methods such as ultrasonic vibration and the addition of special dispersants can be used for wet testing. This allows wet testing to handle ultrafine powders that are difficult to disperse. For example, for ultra-fine titanium dioxide in powder coating raw materials, currently only wet testing can reliably detect its particle size distribution.

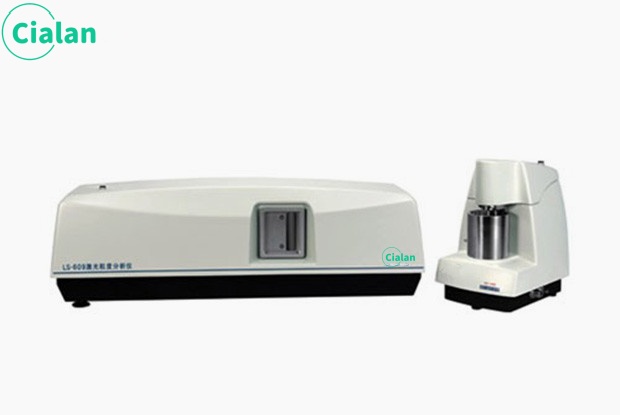

LS-609 laser particle size analyzer

It is an intelligent, high-performance, fully automatic laser particle size analyzer upgraded and developed by Cialan Instrument Company based on the excellent test performance of LS-POP(9). The light source of LS-609 is an imported He-Ne laser, which has more stable power and shortens the preheating process. At the same time, the instrument adopts an integrated base design, which requires no optical path maintenance for regular use. The overall cover design also makes it dustproof and waterproof, and can adapt to harsh working environments. In terms of operability, the software has SOP standard operating process functions. The particle size testing process is more concise and efficient, the test results are more stable and reliable, and the comparison of particle size testing reports is more intuitive and simple.

Cialan is deeply involved in the coatings industry and always pays attention to understanding market trends and customer needs. For the coatings industry, it has formed a matrix of related supporting products and particle size detection solutions such as wet laser particle size analyzers, dry laser particle size analyzers, and nanoparticle size potential analyzers. Make contributions to the best of our ability to improve the quality and efficiency of the industry.

Wet dispersion method.

Wet testing is a commonly used testing method in the coating industry for water-based acrylic coatings, water-based coatings, powder coatings, etc. Since water is a good conductor of sound waves and a universal solvent, additional dispersion methods such as ultrasonic vibration and the addition of special dispersants can be used for wet testing. This allows wet testing to handle ultrafine powders that are difficult to disperse. For example, for ultra-fine titanium dioxide in powder coating raw materials, currently only wet testing can reliably detect its particle size distribution.

LS-609 laser particle size analyzer

It is an intelligent, high-performance, fully automatic laser particle size analyzer upgraded and developed by Cialan Instrument Company based on the excellent test performance of LS-POP(9). The light source of LS-609 is an imported He-Ne laser, which has more stable power and shortens the preheating process. At the same time, the instrument adopts an integrated base design, which requires no optical path maintenance for regular use. The overall cover design also makes it dustproof and waterproof, and can adapt to harsh working environments. In terms of operability, the software has SOP standard operating process functions. The particle size testing process is more concise and efficient, the test results are more stable and reliable, and the comparison of particle size testing reports is more intuitive and simple.