How to choose the right rotational speed of variable frequency planetary ball mill?

How to choose the right rotational speed of variable frequency planetary ball mill?

.jpg)

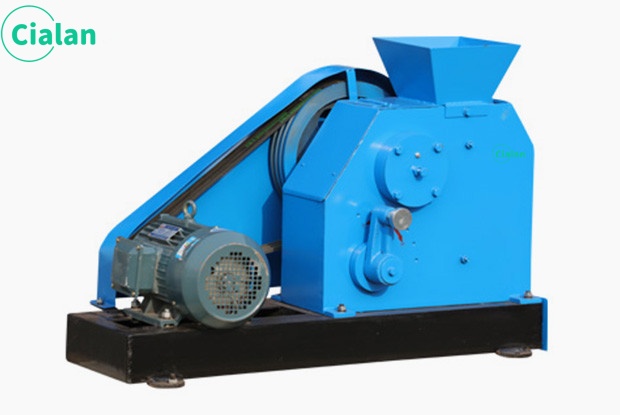

1. cialan Instruments provides frequency conversion planetary ball mill because of the use of frequency converter control, can do step-less speed, but in our grinding process, the speed is not the faster the better, in addition to part of the special materials, small planetary ball mill speed can reach 600rpm can reach the requirements.

2. The rotational speed of the frequency conversion planetary ball mill is an important parameter that affects the performance efficiency, discharge particle size, and grinding energy, but its rotational speed is not that the higher the better, but there is a reasonable range. Finding out this reasonable range will let the performance of the planetary ball mill get full play, processing materials with half the effort.

3. We always think that the higher the rotational speed of the frequency planetary ball mill, the grinding ball in the grinding will get more energy, but the actual situation is not quite the same. In the ball milling process, the planetary ball mill speed increases will lead to the ball milling jar and grinding ball speed increases, when the speed reaches a certain critical value or above, the grinding ball by the centrifugal force of the ball milling jar is greater than by the centrifugal force of the main disk, the grinding ball will be with the wall of the ball milling jar running to reduce the impact on the material, the efficiency of the ball milling and energy reduction.

4. In planetary ball mills in high-speed operation, the faster the rotational speed of the relative ball milling system, the faster the temperature rises, the temperature is too high for most of the material grinding is unfavorable. It will not only lead to the decomposition of oversaturated solid solution, amorphous phase, or other sub-stable phases needed for ball milling but also may cause spontaneous combustion or explosion of powder and other safety hazards.

.jpg)

1. cialan Instruments provides frequency conversion planetary ball mill because of the use of frequency converter control, can do step-less speed, but in our grinding process, the speed is not the faster the better, in addition to part of the special materials, small planetary ball mill speed can reach 600rpm can reach the requirements.

2. The rotational speed of the frequency conversion planetary ball mill is an important parameter that affects the performance efficiency, discharge particle size, and grinding energy, but its rotational speed is not that the higher the better, but there is a reasonable range. Finding out this reasonable range will let the performance of the planetary ball mill get full play, processing materials with half the effort.

3. We always think that the higher the rotational speed of the frequency planetary ball mill, the grinding ball in the grinding will get more energy, but the actual situation is not quite the same. In the ball milling process, the planetary ball mill speed increases will lead to the ball milling jar and grinding ball speed increases, when the speed reaches a certain critical value or above, the grinding ball by the centrifugal force of the ball milling jar is greater than by the centrifugal force of the main disk, the grinding ball will be with the wall of the ball milling jar running to reduce the impact on the material, the efficiency of the ball milling and energy reduction.

4. In planetary ball mills in high-speed operation, the faster the rotational speed of the relative ball milling system, the faster the temperature rises, the temperature is too high for most of the material grinding is unfavorable. It will not only lead to the decomposition of oversaturated solid solution, amorphous phase, or other sub-stable phases needed for ball milling but also may cause spontaneous combustion or explosion of powder and other safety hazards.