Cialan teaches you how to install a double-layer glass reactor and its features.

Installation steps of double-layer glass reactor.

1. After unpacking the glass reactor, check whether the main accessories of the machine are complete according to the packing list.

2. Assemble the stainless steel pipe and fixings to the frame as shown in the attached drawing.

3. Install the electrical box on the top of the right rear pole, tighten the screws, and plug in the seven-pin plug. The vacuum gauge is installed at the rear end, just tighten the screws.

4. According to the height of use, fix the circular bracket of the cauldron on the vertical pole slider. Place the cauldron on the bracket. The semicircular hoop is used to fix the neck of the cauldron and insert it into the vertical pole slider respectively. Tighten the fixing screws after closing. When installing, make sure the main body of the reactor is vertical.

5. The stirring rod is fixed on the ring chuck of the motor spindle. The stirring rod passes through the rotating bearing in the middle of the cover. Tighten the special connector, and then adjust the position of the motor, paying attention to the vertical concentricity.

6. The slider on the vertical pole is a stainless steel multi-purpose clip that can be fixed and adjusted in different directions and heights.

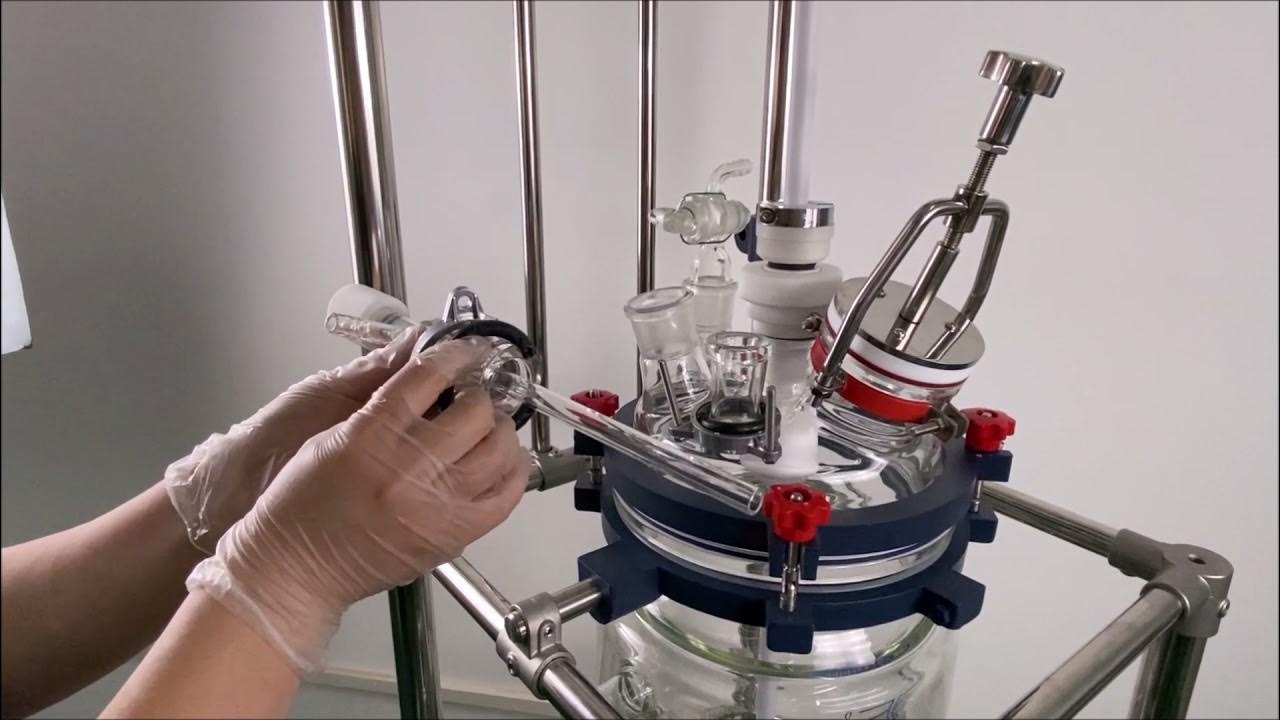

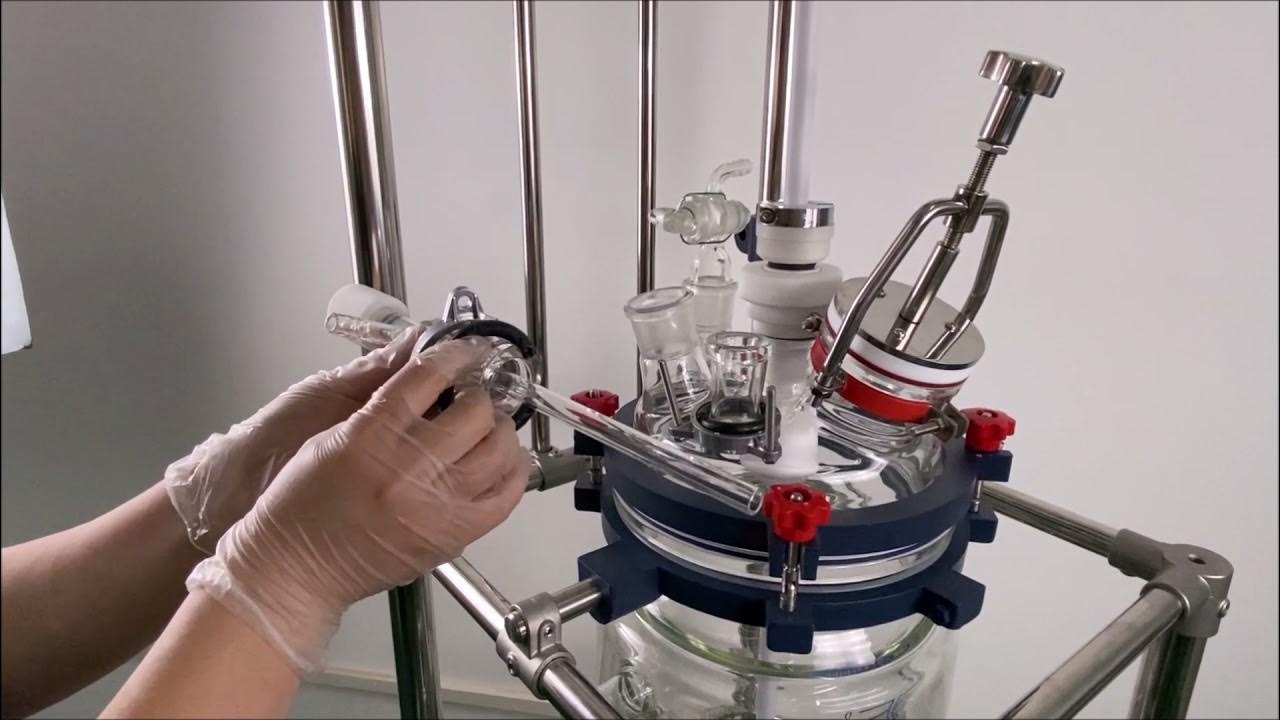

7. The 40# standard port on the left side of the bottle cap is inserted into the snake-type reflux condenser, the 40# standard port on the right is the feeding port connected to the constant pressure funnel, the 24# standard port in the middle and front is for inserting the thermometer sleeve, and the 34# standard port at the back of the cap It is a multi-functional spare port with a discharge valve at the bottom, and the upper and lower parts of the kettle are respectively the inlet and outlet of the circulating fluid. The lower port is connected to the circulating fluid inlet, and the upper port is connected to the circulating fluid return port.

8. When installing glass instruments, they must be clean. Apply Vaseline on each interface to prevent the glass from locking, and then apply vacuum grease to prevent air leakage.

9. Press the universal wheel fixing device of the glass reactor to stir. If the stirring is stable, it means that the debugging is complete.

Features to glass reactor.

●The motor is a DC variable frequency motor with large torque. The motor does not generate heat or sparks when running continuously. It has high efficiency and low noise. The digital display shows the real speed instead of the simulated speed.

●The material of the kettle body is GG17 high borosilicate glass, which has excellent physical and chemical properties. It is resistant to high-temperature differences of 80 degrees and can be used in large temperature areas from high temperature (300℃) to low temperature (-80℃).

●Can work under normal pressure and vacuum conditions, and the vacuum degree in a static state can reach below 0.095MPa.

●The kettle body is fixed with tray-type bakelite gaskets, which have good stability and are resistant to acid and alkali corrosion.

●Anti-corrosion discharge valve with no dead space design.

1. After unpacking the glass reactor, check whether the main accessories of the machine are complete according to the packing list.

2. Assemble the stainless steel pipe and fixings to the frame as shown in the attached drawing.

3. Install the electrical box on the top of the right rear pole, tighten the screws, and plug in the seven-pin plug. The vacuum gauge is installed at the rear end, just tighten the screws.

4. According to the height of use, fix the circular bracket of the cauldron on the vertical pole slider. Place the cauldron on the bracket. The semicircular hoop is used to fix the neck of the cauldron and insert it into the vertical pole slider respectively. Tighten the fixing screws after closing. When installing, make sure the main body of the reactor is vertical.

5. The stirring rod is fixed on the ring chuck of the motor spindle. The stirring rod passes through the rotating bearing in the middle of the cover. Tighten the special connector, and then adjust the position of the motor, paying attention to the vertical concentricity.

6. The slider on the vertical pole is a stainless steel multi-purpose clip that can be fixed and adjusted in different directions and heights.

7. The 40# standard port on the left side of the bottle cap is inserted into the snake-type reflux condenser, the 40# standard port on the right is the feeding port connected to the constant pressure funnel, the 24# standard port in the middle and front is for inserting the thermometer sleeve, and the 34# standard port at the back of the cap It is a multi-functional spare port with a discharge valve at the bottom, and the upper and lower parts of the kettle are respectively the inlet and outlet of the circulating fluid. The lower port is connected to the circulating fluid inlet, and the upper port is connected to the circulating fluid return port.

8. When installing glass instruments, they must be clean. Apply Vaseline on each interface to prevent the glass from locking, and then apply vacuum grease to prevent air leakage.

9. Press the universal wheel fixing device of the glass reactor to stir. If the stirring is stable, it means that the debugging is complete.

Features to glass reactor.

●The motor is a DC variable frequency motor with large torque. The motor does not generate heat or sparks when running continuously. It has high efficiency and low noise. The digital display shows the real speed instead of the simulated speed.

●The material of the kettle body is GG17 high borosilicate glass, which has excellent physical and chemical properties. It is resistant to high-temperature differences of 80 degrees and can be used in large temperature areas from high temperature (300℃) to low temperature (-80℃).

●Can work under normal pressure and vacuum conditions, and the vacuum degree in a static state can reach below 0.095MPa.

●The kettle body is fixed with tray-type bakelite gaskets, which have good stability and are resistant to acid and alkali corrosion.

●Anti-corrosion discharge valve with no dead space design.