Vacuum drying ovens experience of use.

Vacuum drying oven' experience of use.

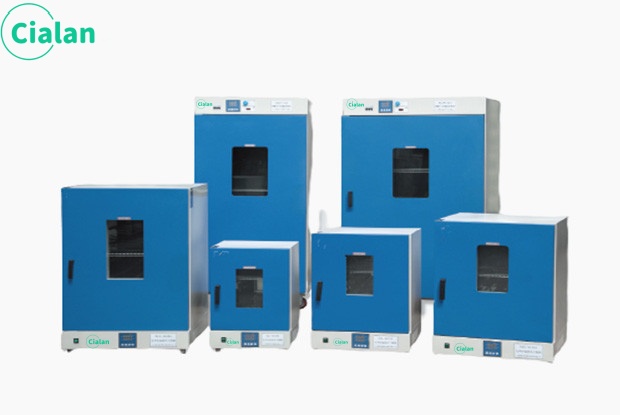

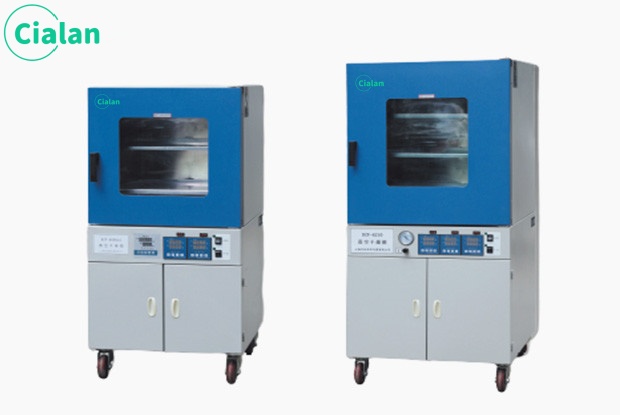

A vacuum drying oven is widely used in the electronics and chemical industry, especially suitable for drying heat-sensitive, easy-to-decompose, easy-to-oxidize substances and complex compositions of goods for rapid and efficient drying treatment. The following points are summarized for your reference only.

1. The vacuum pump can not work for a long time, so when the vacuum degree reaches the requirement of drying articles, the vacuum valve should be closed first, and then off the power supply of the vacuum pump, when the vacuum degree is less than the requirement of drying articles, open the vacuum valve and the power supply of the vacuum pump to continue to pump the vacuum, to prolong the service life of the vacuum pump.

2. If the vacuum drying oven has not been used for a long time, wipe the exposed plating parts clean and coat them with neutral grease to prevent corrosion, put on the plastic film dust cover, and place it in a dry room to avoid the damage of the electrical components by moisture, which will affect the use.

3. For dry items such as moisture, it is best to add filters between the vacuum drying box and the vacuum pump to prevent moisture gas from entering the vacuum pump, resulting in vacuum pump failure.

4. Dry items such as drying change to a lightweight, small volume (for small particles), should be in the working chamber vacuum port plus barrier net, to prevent the dry material inhalation and damage to the vacuum pump (or solenoid valve).

5. The vacuum drying box after many times of use, such as the phenomenon of not being able to vacuum, at this time should be replaced to solve the sealing strip. When the vacuum box drying temperature is higher than 200 ℃, such as the phenomenon of slow leakage, this time to disassemble the box back cover plate with an Allen wrench to loosen the base of the heater, replace the sealing ring, or tighten the base of the heater to solve the problem.

6. If it is difficult to rotate the rubber plug of the bleeder valve, it can be lubricated with the appropriate amount of grease.

7. In addition to maintenance, can not remove the left side of the box cover to avoid damage to the electrical control system.

8. Vacuum drying oven should be kept clean. Box door glass should not be wiped with a reactive chemical solution, should be wiped with a soft cotton cloth.

A vacuum drying oven is widely used in the electronics and chemical industry, especially suitable for drying heat-sensitive, easy-to-decompose, easy-to-oxidize substances and complex compositions of goods for rapid and efficient drying treatment. The following points are summarized for your reference only.

1. The vacuum pump can not work for a long time, so when the vacuum degree reaches the requirement of drying articles, the vacuum valve should be closed first, and then off the power supply of the vacuum pump, when the vacuum degree is less than the requirement of drying articles, open the vacuum valve and the power supply of the vacuum pump to continue to pump the vacuum, to prolong the service life of the vacuum pump.

2. If the vacuum drying oven has not been used for a long time, wipe the exposed plating parts clean and coat them with neutral grease to prevent corrosion, put on the plastic film dust cover, and place it in a dry room to avoid the damage of the electrical components by moisture, which will affect the use.

3. For dry items such as moisture, it is best to add filters between the vacuum drying box and the vacuum pump to prevent moisture gas from entering the vacuum pump, resulting in vacuum pump failure.

4. Dry items such as drying change to a lightweight, small volume (for small particles), should be in the working chamber vacuum port plus barrier net, to prevent the dry material inhalation and damage to the vacuum pump (or solenoid valve).

5. The vacuum drying box after many times of use, such as the phenomenon of not being able to vacuum, at this time should be replaced to solve the sealing strip. When the vacuum box drying temperature is higher than 200 ℃, such as the phenomenon of slow leakage, this time to disassemble the box back cover plate with an Allen wrench to loosen the base of the heater, replace the sealing ring, or tighten the base of the heater to solve the problem.

6. If it is difficult to rotate the rubber plug of the bleeder valve, it can be lubricated with the appropriate amount of grease.

7. In addition to maintenance, can not remove the left side of the box cover to avoid damage to the electrical control system.

8. Vacuum drying oven should be kept clean. Box door glass should not be wiped with a reactive chemical solution, should be wiped with a soft cotton cloth.