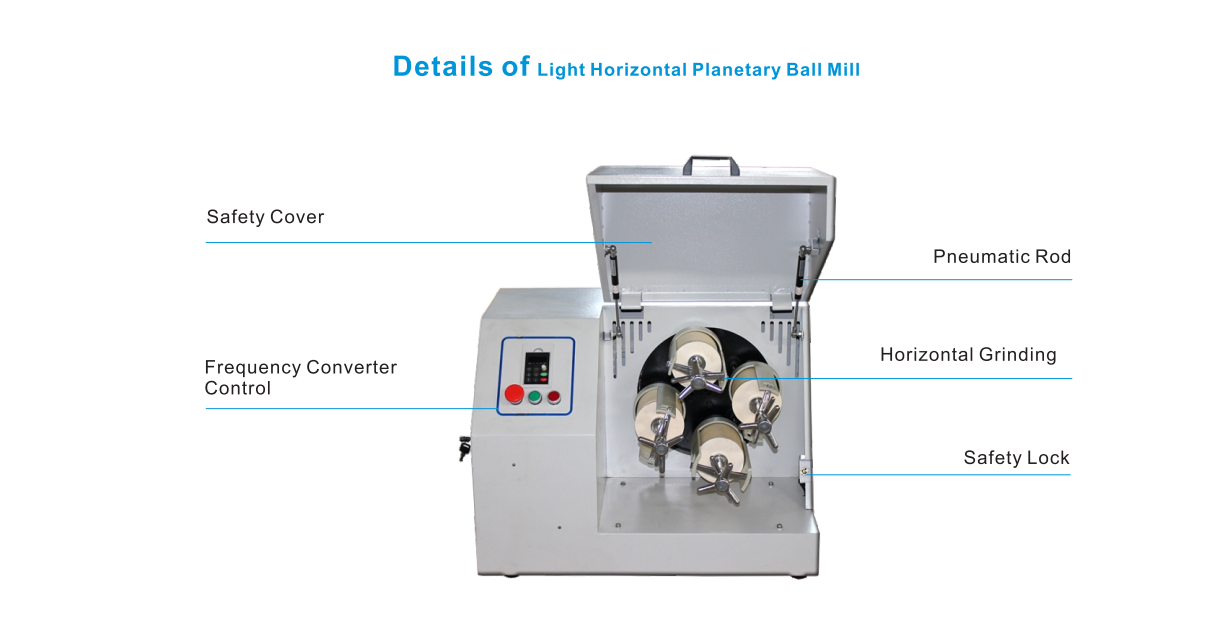

Light Horizontal Planetary Ball Mill

The light horizontal planetary mill has simple structure and convenient operation, and is suitable for laboratory small batch sample experimental research.

Horizontal grinding

0.4L~6L

Capacity

2~4

Work position

.jpg)

.jpg)

.jpg)